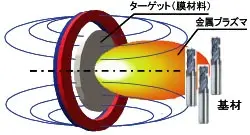

Hard coating by AIP

AIP is an ion plating process utilizing arc discharge in a vacuum environment. The plasma-strengthened cathode enables more functionally advanced film formation.

Features

- Dense and high hardness

- High adhesion

- Multiple alloy compositions are also available

Lineup of BELCOAT™ by AIP®

| Name | Film type | Color | Oxidation (°C) | Typical applications |

|---|---|---|---|---|

| BELCOAT G | TiN |

|

600 | Cutting tools (general-purpose cutting) Dies (press, cold forging) |

| BELCOAT R2 | TiCN |

|

400 | Cutting tools (wet high-speed cutting) Dies (press, cold forging) |

| BELCOAT V | TiAIN |

|

800 | Cutting tools (high-speed dry cutting) Dies (warm and hot forging) |

| BELCOAT SG | CrN |

|

700 | Cutting tools (nonferrous metal cutting) Dies (die-cast, press, cold forging) |

| BELCOAT SDG | TiCrAlN monolayer |

|

1,000 | Cutting tools (high-speed dry cutting of low to high-hardened materials) |

| BELCOAT SS | TiCrAlN multilayer |

|

1,100 | Dies (press, cold to hot forging) |

- *In addition to the above, we also offer a wide variety of film coatings to meet your requirements.

Applications of BELCOAT™ by AIP®

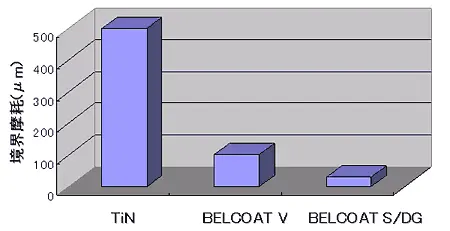

Cutting tool (1) High-speed dry milling of carbon steel

| Tool | Carbide ball EM (R5) |

|---|---|

| Target | SCM430(HB220) |

| Machining speed (m/min) | 100 |

| Feed (mm/tooth) | 0.05 |

| Axial depth of cut (mm) | 4.5 |

| Radial depth of cut (mm) | 0.5 |

| Lubrication | Dry and air blow |

| Cutting length (m) | 30 |

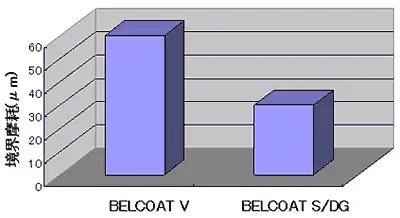

Cutting tool (2) High-speed dry milling of hardened tool steel

| Tool | 2-flute carbide EM-R5 |

|---|---|

| Target | SKD61(HRC50) |

| Machining speed (m/min) | 220 |

| Feed (mm/tooth) | 0.06 |

| Axial depth of cut (mm) | 5 |

| Radial depth of cut (mm) | 0.6 |

| Lubrication | Dry and air blow |

| Cutting length (m) | 30 |

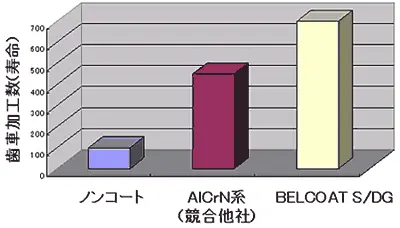

Cutting tool (3) Cutting of carbon steel gears

| Tool | Carbide tooth cutter |

|---|---|

| Target | SCM |

| Machining speed (m/min) | 190 |

| Feed (mm/tooth) | 0.05-0.13 |

| Axial depth of cut (mm) | |

| Radial depth of cut (mm) | |

| Lubrication | Dry and air blow |

| Cutting length |

Cutting tool (4) Cutting of carbon steel gears

| Tool | HSS gear cutting tool |

|---|---|

| Target | SCM |

| Machining speed (m/min) | 190 |

| Feed (mm/tooth) | 0.05-0.13 |

| Axial depth of cut (mm) | |

| Radial depth of cut (mm) | |

| Lubrication | MQL |

| Cutting length |

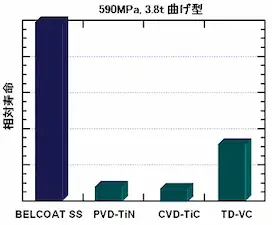

Press forming die (1) Comparison between BELCOAT SS and conventional surface treatments

| BELCOAT SS | TD-VC | CVD-TiC | |

|---|---|---|---|

| Deposition method | PVD (AIP) | Thermal diffusion process | CVD |

| Processing temperature | 400 - 450℃ | 900 - 1,000℃ | 900 - 1,000℃ |

| Thermal distortion of tooling | 0.02% or less | Approx. 0.1% | Approx. 0.1% |

| Film hardness | 35GPa | 35GPa | 30GPa |

| Oxidation temperature | 1,000℃ | 500℃ | 500℃ |

| Load-bearing capacity | Very good | Good | Poor |

- Low processing temperature and little thermal distortion

- High load-bearing capacity

- Composition design that allows for extremely good anti-oxidation properties

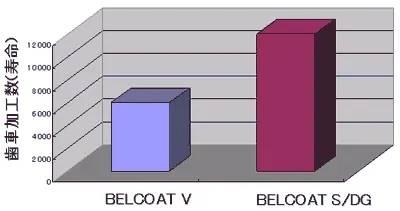

Press forming die (2)

Press forming of high-tensile strength steel

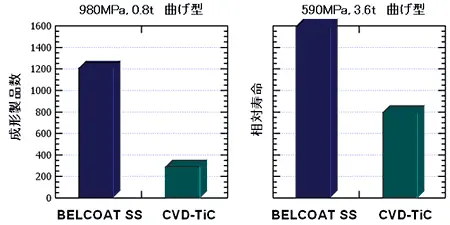

Press forming die (3)

Press forming of high-tensile strength steel

Coating capabilities of AIP equipment

| Applicable dimensions |

|

|---|---|

| Materials suitable for coating |

Carbide, SUS, tool steel, die steel, etc.

|

| Processing temperature |

400~600℃

|

| Thickness |

1 to 50 μm

|

Contact Us

You can reach us by clicking the inquiry button.