Steel Rolling Mills

Rolling Mills

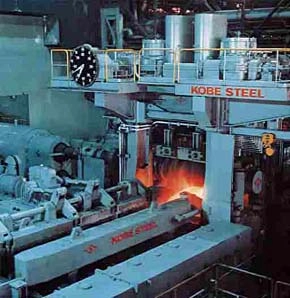

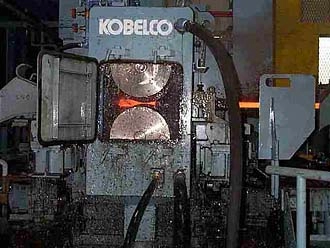

Blooming & Billet Mill

- We can design and manufacture the stand shift-type reversing rolling mill (shiftable reversing mill).

- Highly rigid mill stand

- Short roll changing time (within 15 minutes)

Compact Mill: Kobelco Compact Mill (KCS MILL)

- The mill stand is positioned in a short span, allowing for stable rolling while minimizing temperature loss in rolling stock.

- Non-twist rolling with alternate horizontal and vertical arrangement

- Compact design, enabling space-saving installation

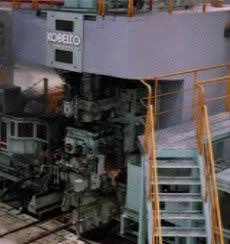

Conventional Mill Stands (Vertical)

- The conventional up-drive type mill stand consists of a roll stand, mill spindles, a vertical gear reducer with a pinion stand and a motor. The gear reducer and motor are mounted on a concrete frame to keep them from roll cooling water and mill scale.

- A lifting device is installed under the roll stand to adjust the caliber position to the pass level. The roll stand can be moved to the work side when changing the stand.

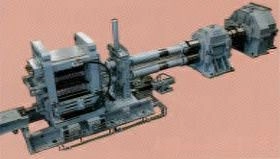

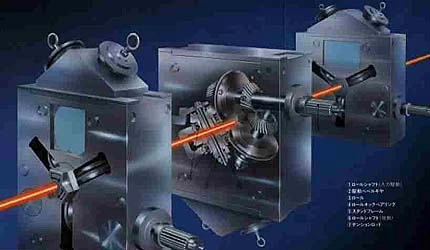

Conventional Mill Stands (Horizontal)

- The horizontal-type conventional mill stand consists of a roll stand, a pinion stand, a gear reducer and a motor. In the case of a constant pass line, the roll stand slides on the surface of the sole plate. In a low-speed rolling mill with less than 10 m/sec, the pinion stand and gear reducer form a single unit.

- A cross pin joint is used for the mill spindle and is supported by the spindle carrier during rolling.

Convertible Mills (Horizontal & Vertical)

- According to the pass schedule, one stand can be used as both a horizontal and vertical stand.

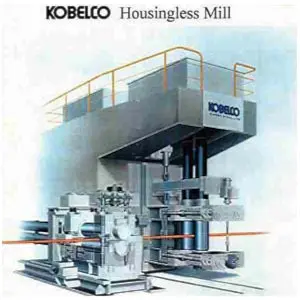

Housingless Mills

- The stand is lighter than conventional types, making it easier to change the stand.

- Symmetrical pressure reduction maintains the pass center constant.

- The roll changer allows for easy and quick roll changes.

- A drive unit and stand lifting unit are installed on the top of the stand for easy maintenance.

Cantilever Mills

- Compact design, saving space for installation

- Downtime minimized by:

- Quick size changes with stand shifting mechanism (optional)

- Quick roll changes with built-in quick roll disconnecting mechanism

- Quick guide setting with one-touch setup mill guide (optional)

- Symmetrical rolling by remore control

- Excellent operability—easy visual inspection and access to the rolled material

- Sufficient mill rigidity, equivalent to that of the conventional mill stands

Block Mill: Kobelco Super High Unit Mill (S-HUM)

- Super high speed rolling (Designed rolling speed : 140 m/sec)

- Free combination of different roll size stands according to the product size, steel grade and pass schedule

- Downtime is minimized by X-arrangement of stands and easy guide roll setting

- Easy misroll processing due to internal piping in the trough

- Applicable to bars with a design rolling at 40 m/sec. (S-HUM FOR BAR)

Three Roll Mill: Kobelco Super Three Roll Mill (STR-Mill)

- Precision rolling with high dimentional accuracy

- Three types of models are available for specific applications: Precision rolling, three-roll multi-stand, compatible with the 2-high stand

Merit Matrix

A: Excellent

B: Good

C: Moderate (Major strengths demonstrated in other areas)

B: Good

C: Moderate (Major strengths demonstrated in other areas)

| Rolling mill models | Advantage for customers | ||||

|---|---|---|---|---|---|

| Productivity | Product quality | Economical | Man-power saving | Other | |

| Shiftable Reverse Mill | B | C | |||

| Compact Mill: Kobelco Compact Mill (KCS MILL) |

B | C | Space-saving | ||

| H/V Convertible Mill | Diversifying product types | ||||

| Cantilever Mill | C | B | C | Space-saving | |

| Housingless Mill | B | Space-saving | |||

| Block Mill: Kobelco Super High Unit Mill (S-HUM) |

A | ||||

| (S-HUM FOR BAR) | A | A | |||

| Three Roll Mill: Kobelco Super Three Roll Mill (STR-Mill) |

B | A | |||

Contact Us

You can reach us by clicking the inquiry button.