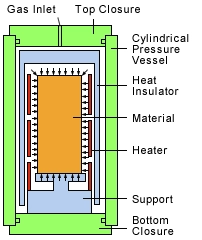

Hot Isostatic Press (HIP) Equipment

Hot Isostatic Pressing (HIP) is a material processing method that compresses materials by simultaneously applying high temperature of several hundreds to 2000℃ and isostatic pressure of several tens to 200 MPa. Argon is the most widely used pressure medium.

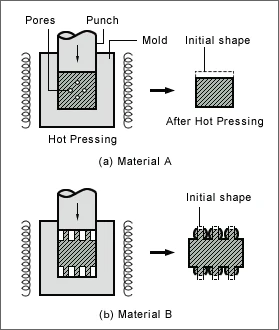

Hot pressing is very similar to HIP. Milling, forging, extrusion also apply high temperature and pressure, but not isostatic pressure unlike HIP.

Difference between HIP and Hot Pressing

HIP applies isostatic pressure to materials using gas pressure, while hot pressing applies only uniaxial pressure.

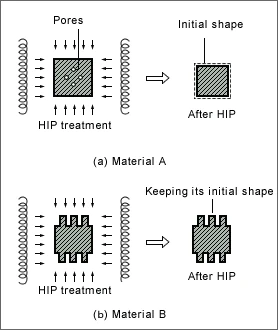

To explain the difference of HIP and hot pressing clearly, suppose that HIP or hot pressing is applied to Material A (metal with pores inside) and Material B (metal with uneven ends).

In the case of HIP, Material A, as shown in Figure 1, will contract keeping its initial shape until pores inside disappear, and bond together due to diffusion effects. On the other hand, Material B undergoes no shape change at all because uniform pressure is applied to the uneven edges.

In the case of hot pressing, the same phenomena as the case of HIP occur to Material A, which is shown in Figure 2. Material B, however, can't keep its initial uneven shape because pressure is applied only to the convex portions. Both Material A and Material B will have different final shapes after hot pressing depending on shapes of a mold and a punch used. Fabrication of large products and moldings under high temperature might be difficult due to ununiformity caused by friction force with a mold, as well as temperature and demention constraints depending on the strength of mold materials.

Compared to hot pressing, HIP can maintain material shapes that are not much different from the original after pressure. Even after altering shape, the material can keep its original shape, and will have less restrictions in product processing. Because of these benefits, HIP has been applied in various fields.

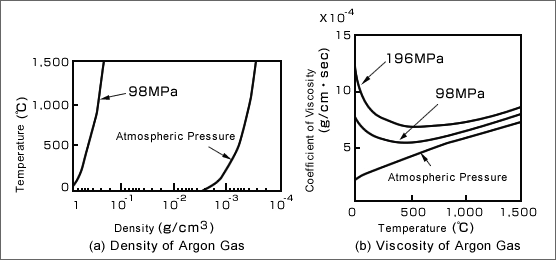

Pressure Medium Gas (Argon Gas) under High Pressure

Argon gas at 1000℃ and under pressure of 98 MPa is likely to cause intense convection due to its low density and viscosity coefficient (30% and 15% of water, respectively), as well as high thermal expansion coefficient. Therefore, HIP equipment's heat transfer coefficient is higher than that of a typical electronic furnace.

HIP Applications

HIP is applied in a wide range of fields as follows:

- 1Pressure sintering of powder

- 2Diffusion bonding of different types of materials

- 3Removal of residual pores in sintered items

- 4Removal of inner defects of castings

- 5Rejuvenation of parts damaged by fatigue or creep

- 6High pressure impregnated carbonization method

| Applied Technology | Practical Application | Material under Study |

|---|---|---|

| Pressure sintering of powder | PM high speed steel (jigs), Ni-based superalloys (engine turbine discs), Ti alloys (aircraft components), Cr (target) | Ti-Ni alloy, amorphous metal, Si3N4, SiC |

| Diffusion bonding(Production of composites) | Nuclear fuel assemblies (nuclear reactors), B fiber-Al alloy composites (space shuttle struts), various corrosion/abrasion-resistant alloy composite parts (valves for corrosive gas, mill roll, cylinders for injection molding machines etc.) | SiC-Al alloy composites, Nb3Sn-copper, Si3N4-stainless steel |

| Removal of residual pores in sintered items | Cemented carbide (jigs), Al2O3(cutting tools), Al2O3-TiC (cutting tools), soft ferrites (magnetic head), Si3N4 (bearings and ceramics structure) | SiC, PSZ, ZnSe |

| Removal of inner defects of castings | Al alloys, Ni-base superalloys (jet engine turbine blades), Ti alloys (aircraft components), 17-4PH stainless steel | |

| Rejuvenation of parts damaged by fatigue or creep | Superalloy precision castings (gas turbine blades) | |

| High pressure impregnated carbonization method | Carbon composites |

HIP Treatment

Materials require various HIP treatments according to their characteristics. The most common methods are the Capsule Method and Capsule Free Method.

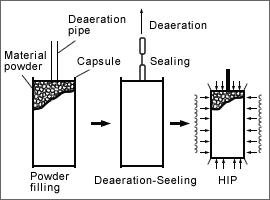

The Capsule Method, as shown in the right figure, is to carry out HIP after enclosing powder or a body molded from powder in a gastight capsule and evacuating the capsule.

The Capsule Method can achieve high densification even for materials that are difficult to sinter using conventional sintering techniques. This makes it the most commonly adopted pressure sintering process for powder materials. It is also used for diffusion bonding of different types of materials and high pressure impregnated carbonization processes.

The table below gives a list of main materials for capsule free methods and HIP treatment temperature/pressure.

Materials for capsule free methods

| Material | Temperature | Pressure |

|---|---|---|

| Powder high-speed steel | 1,000 to 1,200℃ | to 100MPa |

| Ni base alloy | 1,170 to 1,280℃ | 100 ~ 150MPa |

| Ti alloy (Ti-6Al-4V) | 880 to 960℃ | to 100MPa |

| Cr | 1,200 to 1,300℃ | to 100MPa |

| Cu Alloy | 500 to 900℃ | to 100MPa |

| Al Alloy | 350 to 500℃ | to 100MPa |

| Cemented carbide (WC-Co) | 1,300 to 1,350℃ | 30 to 100MPa |

| Ti Ba O3 | 1,000 to 1,200℃ | to 100MPa |

| PZT | 950 to 1,150℃ | to 100MPa |

| Ni-Zn-ferrite | 1,050 to 1,180℃ | to 100MPa |

| Mn-Zn-ferrite | 1,180 to 1,250℃ | to 100MPa |

| Al2O3 | 1,350 to 1,450℃ | to 100MPa |

| Y-PSZ (yttria partially-stabilized zirconia) | 1,350 to 1,500℃ | to 100MPa |

| Si3N4-Al2O3-Y2O3 | 1,700 to 1,800℃ | to 100MPa |

| SiC | 1,950 to 1,050℃ | 100 to 200MPa |

Meanwhile, if the pores inside the material are isolated, closed off, and not connected to the surface of the material, these pores are squashed and eliminated by HIP treatment. On the other hand, open pores that connect with the surface of the material are not squashed even after HIP treatment. Therefore, HIP treatment to the material with the closed pores can achieve high densification throughout entire material.

Such materials do not require capsules for HIP treatment, which is known as the Capsule Free Method. This method is used to remove residual pores from sintered items, remove inner defects of castings, and rejuvenate parts damaged by fatigue or creep.

HIP Effects

HIP treatment to castings can improve creep fracture lifetime by 1.3 to 3.5 times, elongation, and contraction, depending on the types of alloys, as shown in the Table below.

| Alloy | State | Test Conditions | Lifetime | Elongation | Contraction | |

|---|---|---|---|---|---|---|

| Temperature | Stress | |||||

| IN738 | Casting | 1,253K | 152MPa | 68.4x103sec | 11.8% | 20.0% |

| Casting+HIP | 1,253K | 152MPa | 189.0x103sec | 20.5% | 20.6% | |

| Rene77 | Casting | 1,253K | 152MPa | 183.6x103sec | 19.4% | 37.0% |

| Casting+HIP | 1,253K | 152MPa | 244.8x103sec | 22.0% | 55.0% | |

| IN792 | Casting | 1,143K | 310MPa | 630.0x103sec | 9.2% | 6.5% |

| Casting+HIP | 1,143K | 310MPa | 1,018.8x103sec | 12.1% | 22.0% | |

| Rene80 | Casting | 1,143K | 310MPa | 149.4x103sec | 2.5% | 2.5% |

| Casting+HIP | 1,143K | 310MPa | 507.6x103sec | 11.5% | 17.0% | |

Contact Us

You can reach us by clicking the inquiry button.