Air compressors (for semiconductor manufacturing facilities)

Clean compressed air with high efficiency

Air compressors are indispensable utility equipment, which supply industry gases, such as powering air, nitrogen gas, etc. in the factory by compressing air from the environment.

Air compressors can be classified roughly into 2 groups, i.e., oil-injected type and oil-free type: the oil-free type can supply clean air free from oil contamination.

Responsible company: Kobelco Compressors Corporation

Features

- Highest efficiency in the industry

- High durability ensured by our in-house designed & manufactured screw compressors

- Our oil-free compressors can be mass-produced, which is possible by only 4 major companies in the world.

- By-produced thermal energy from compressed air production is reused as hot water.

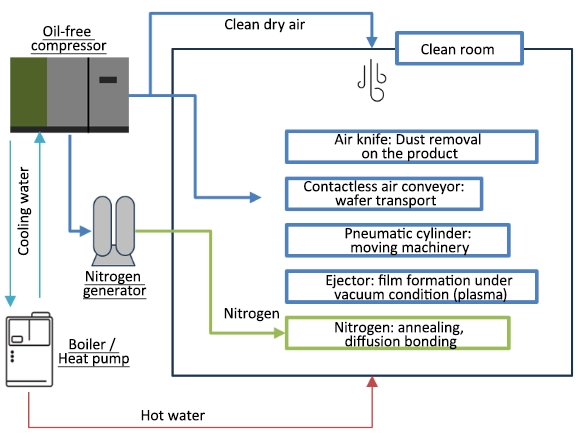

Implementation image in clean room

Air compressors are widely used in many semiconductor manufacturing processes, mainly for “clean room air conditioning” (constant temperature and humidity) and “purified water heating”, and other various processes.

Clean Room Air Conditioning

Clean rooms require extremely high-purity air with a low dew point, low dust, and oil-free characteristics. KOBELCO meets the stringent demands for clean room applications.

Various processes

In semiconductor production processes, we provide clean air for dust removal, wafer transport, operation of machinery, and formation of films under vacuum, as well as nitrogen used as inert gas during annealing and diffusion bonding.

Case study

Product line-up

Contact Us

You can reach us by clicking the inquiry button.