Sputtering targets for oxide semiconductors

The oxide semiconductor material with higher electron mobility than IGZO

The Sputtering Target Business of Kobelco Research Institute Inc. introduces oxide semiconductor sputtering targets for Φ300mm Si wafers.

This material is an oxide semiconductor realized by our own development, showing higher electron mobility and higher TFT reliability than conventional oxide semiconductor (IGZO), with an extensive track record in flat panel display application.

In silicon semiconductor uses, this material has been applied to embedded memory devices, and improvement in the memory operation has been confirmed. KOBELCO proposes this material to contribute to the functional improvement of future edge devices and for the social implementation of artificial intelligence.

Responsible Company: Kobelco Research Institute, Inc. (Japanese site)

Features

- KOS-B03C has higher electron mobility than a-Si and IGZO.

Miniaturization of oxide semiconductor transistors will be realized. - This material can be used in low temperature processes (350oC).

This enables transistor formation in the back-end process. - This is a wide bandgap material capable of film formation by DC sputtering.

This enables transparent transistor formation on a transparent film. - This enables transistor formation with low off-leak electric current.

Hybridization between crystalline Si and oxide semiconductor transistors can contribute to reduce power consumption.

| Thin-film semiconductor material | a-Si | LTPS (low temperature poly-Si) |

Oxide |

|---|---|---|---|

| Electron mobility (cm2/Vs) | 0.5 - 1 | 60 - 100 | IGZO:10 KOS-B03C:20-30 |

| Deposition method | CVD | CVD & Laser Anneal | DC Magnetron Sputtering |

| Large area | Possible | Impossible | Possible |

| Process temperature(℃) | < 350 | < 600 | < 350 |

| Band gap(eV) | 1.4 - 1.8 | 1.1 | 2.9 - 3.3 |

| Off leakage current(A/mm) | 1×10-13 | 1×10-12 | 1×10-16 |

Characteristics

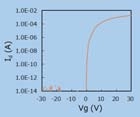

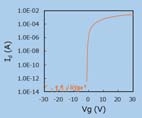

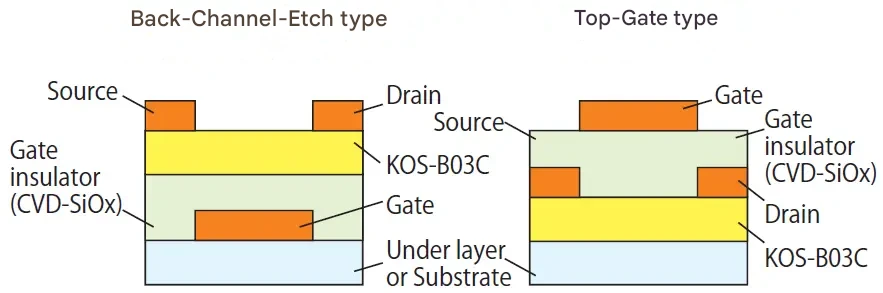

| Back-Channel-Etch type | Top-Gate type | |

|---|---|---|

| Transfer curve |

|

|

| Saturation mobility | 29.1cm2/Vs | 24.4cm2/Vs |

| Vth | 0.50V | -0.75V |

| S.S. | 0.17V/dec. | 0.16V/dec. |

Product line-up

Sputtering targets with various sizes and shapes are available.

Contact Us

You can reach us by clicking the inquiry button.