Low Thermal Expansion Alloy and High-Purity / High-Corrosion-Resistance Stainless Steel

Front-end Process

Manufacturing and Sales of Low Thermal Expansion Alloys High-Purity / High-Corrosion-Resistance Stainless Steel

- Supports small-lot production (300 kg to 2 tons)

- Recyclability through collection and remelting of discarded molds and other customer materials

Handled by: Nippon Koshuha Steel Co., Ltd.

Product Lineup

Low Thermal Expansion Alloy

- Used in equipment such as lithography systems

| Steel Grade Name by Nippon Koshuha Steel Co., Ltd. | Equivalent Steel Grade | Main Components | Example of Manufacturing Size | Physical Properties |

|---|---|---|---|---|

| Rolled Round Bar | Thermal Expansion Coefficient~100℃ (×10-6/℃) |

|||

| KTAIN | Invar | 36Ni-Fe | Φ20~120 | 0.5~2.0 |

| KTASI | Super Invar | 32Ni-4Co-Fe | 0.01~0.5 |

- *Wire rods also manufacturable

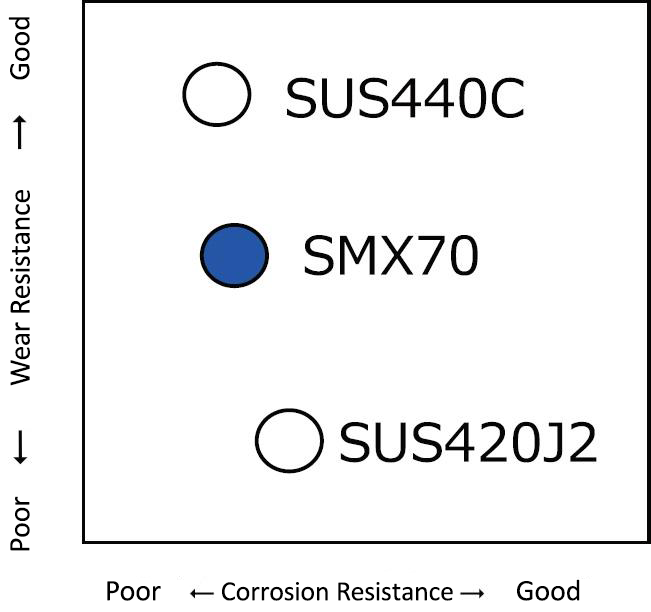

High-Hardness Martensitic Stainless Steel

- Used in linear motion bearings incorporated into semiconductor manufacturing equipment

- Adopted by major linear guide manufacturers

| Steel Grade Name by Nippon Koshuha Steel Co., Ltd. | Main Components | Example of Manufacturing Size | Features |

|---|---|---|---|

| Rolled Wire Rod | |||

| SMX70 | 0.6%C-13%Cr | Φ5.5~24 |

|

- ※Bar steel also manufacturable

Contact Us

You can reach us by clicking the inquiry button.