Heat pumps (for semiconductor factories)

Energy saving equipment providing large thermal energy with small input energy

Heat pumps generate cold/warm water by heat-exchange between water and a refrigirant cooling medium. As energy saving equipment they can significantly cut running costs because the obtained thermal energy is several times more than the input energy, thus helping to realize decarbonization in the semiconductor manufacturing process.

Responsible company: Kobelco Compressors Corporation (Japanese site)

Features

- The highest efficiency in the industry

- High durability due to the use of our own screw compressors

- Wide range of supply temperature (cold water down to 5℃, warm water up to 95℃)

- Overwhelming space saving compared with other heat source equipment.

Implementation image in clean room

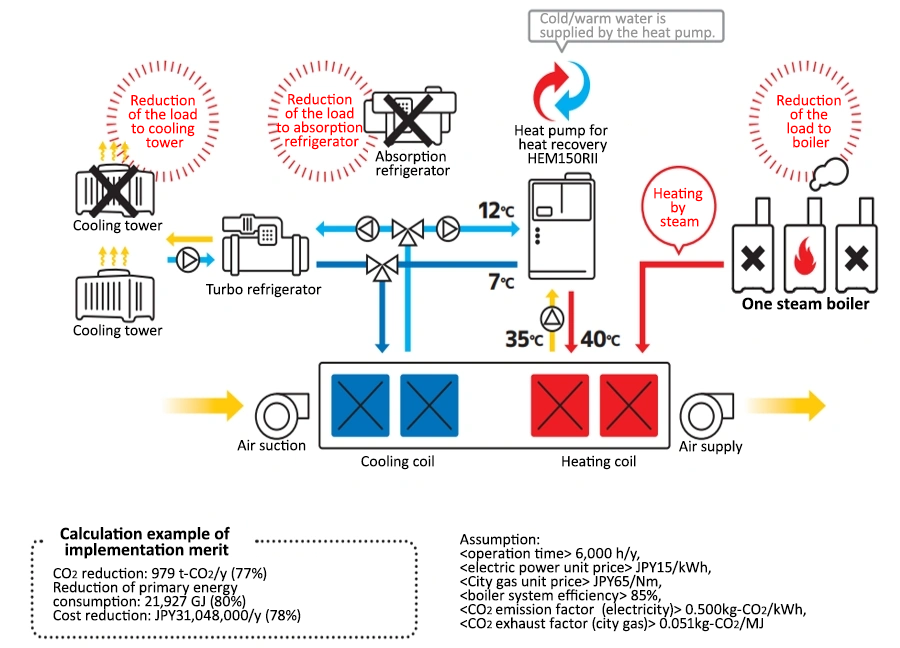

Air conditioning of clean rooms

Uses cold water for dehumidification inside the clean room and warm water for reheating. Replacing the conventional system of “cold water chiller + steam boiler” with a heat pump can achieve large energy savings and CO2 reduction.

Pure water heating

Heat pumps can be utilized for heat recovery from warm waste water. When warm water generated by the recovery of exhaust heat is used to heat the Pure Purified water for semiconductor cleaning, and the heat source is changed from a boiler to a heat pump, it is possible to improve energy efficiency.

Implementation examples

Product line-up

Contact Us

You can reach us by clicking the inquiry button.