Multi-High Mills (KT/KST Mill)

12-High Mill (KT Mill)

Product Overview

![12-High Mill (KT Mill) [Roll Arrangement of KT Mill]](/english/products/machinery/rolling/sheet/img/kt-kst-mill_im01.webp)

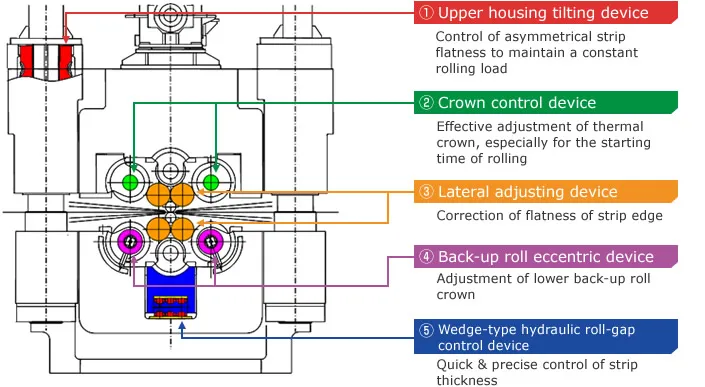

KT Mill (Kobe Twelve-high Mill) is a high-performance rolling mill that combines the qualities of our 4-high and 20-high mills, both of which have excellent strip flatness functions, and meets the demand for improved strip flatness.

The mill employs a number of cutting-edge technologies, including a standard 12-high roll arrangement that provides superior flatness control, our proprietary wedge-type hydraulic roll-gap control system, the Automatic Flatness Control System (AFC), and the Kobelco Operation Support System (KOS), making it an ideal rolling mill for the production of copper alloys, stainless steel, Fe-Ni alloys, and other materials, particularly hard foils.

Standard Specifications

The following are the standard specifications.

Please consult us for further information.

| Type | KT160 | KT260 | KT300 | KT350 |

|---|---|---|---|---|

| WR Diameter | 30–60 | 40–80 | 50–100 | 60–120 |

| Max. Strip width | 650 | 700 | 1,050 | 1,300 |

Structure and Illustration

The Japan Society for Technology of Plasticity

The 2010 Developed Technologies Award for the "Development of KT Mill for stainless steel foil"

- *Publication "JOURNAL OF THE JAPAN SOCIETY FOR TECHNOLOGY OF PLASTICITY" June 2010

20-High Mill (KST Mill)

Product Overview

![20-High Mill (KST Mill) [Roll Arrangement of KST Mill]](/english/products/machinery/rolling/sheet/img/kt-kst-mill_im04.webp)

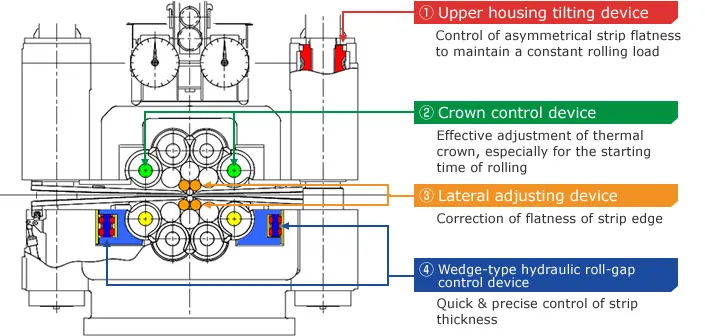

Kobe Super Twenty-High Mill is a 20-high rolling mill (KST Mill) that meets a variety of customer needs, employing unique technologies such as a wedge-type hydraulic roll-gap control system, the Automatic Flatness Control System (AFC), and the Kobelco Operation Support system (KOS), all of which were developed by Kobe Steel with its superior technical capabilites and extensve experience based on conventional 20-high rolling mills.

Its features include advanced automatic thickness control, automatic gauge control, and centralized programmable control of the whole mill line. KST Mill provides the optimal rolling for stainless steel, copper alloy, Fe-Ni alloy, titanium, and other special alloys.

Standard Specifications

The following are the standard specifications.

Please consult us for further information.

| TYPE | KST155 | KST220 | KST260 | KST300 |

|---|---|---|---|---|

| WR Diameter | 30 - 60 | 40 - 80 | 50 - 100 | 60 - 120 |

| Max. Strip width | 650 | 850 | 1,050 | 1,300 |

Structure and Illustration

Structure and Features of Multi-High Mills

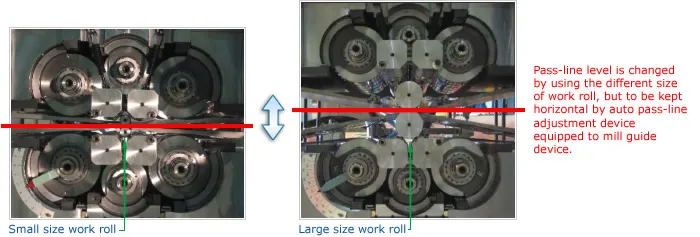

Any Diameter of Work Rolls Applicable

Each series of rolling mills have a specific roll diameter range. For example, KT160 supports work roll sizes ranging from 30 to 60 mm. Work roll sizes can be selected from any diameter within a range of approximately twice the minimum diameter.

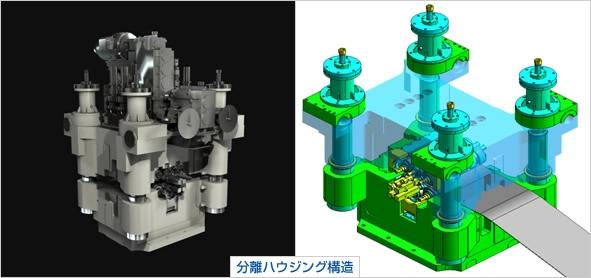

Split-type Housing

Our multi-high rolling mills have a unique housing structure, which is separated into upper and lower parts and connected by four columns.

- Good visibility of the front and back of the strip during rolling and feeding.

- Each of the four columns is equipped with a differential sensor to detect rolling loads.

- Accurate load detection enabled highly accurate Automatic Gage Control (AGC) under hydraulic pressure.

- Screwing down the drive side and work side simultaneously in different directions enables tilting the upper housing separately. The tilting rolling is usufel in correcting strip meandering and asymmetrical shapes.

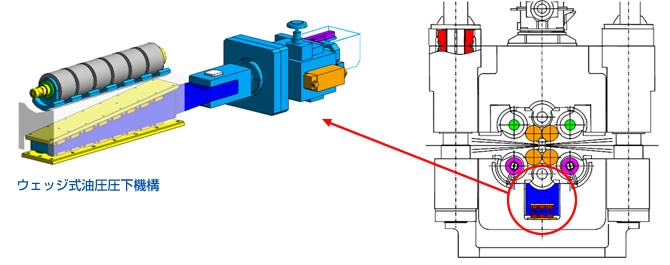

High Gauge Thickness Control by Wedge-Type Hydraulic Roll-Gap Control System

Roll-gap control is performed by the hydraulic cylinder connected to a wedge built in the rear side of the back-up rolls of the lower housing. The rolling load is directly received by the housing through the wedge, enabling high-rigidity hydraulic push-up. The wedge-type hydraulic roll-gap control device also enabled fast displacement control of strip thickness with world-class high-speed control.

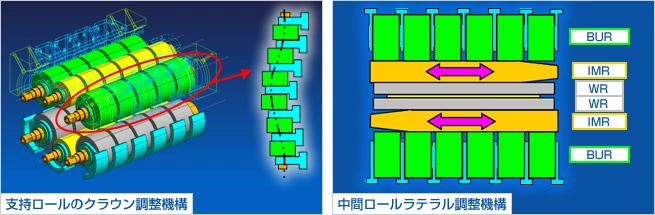

Products with Uniform Shape Guaranteed with Various Flatness Control Mechanisms

Our 12- or 20-high rolling mill is equipped with support roll crown adjustment mechanism, intermediate roll lateral (shift) adjustment mechanism, and tilting-rolling function for shape correction, along with the Automatic Flatness Control System (AFC) for feed back control.

Technical Materials

Contact Us

You can reach us by clicking the inquiry button.