Characteristics of Aluminum

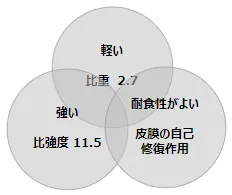

Aluminum is a metal widely used across various industries due to its light weight, strength, corrosion resistance, and workability.

- Aluminum has a density about one-third that of copper or iron, with a high specific strength (strength per unit weight). This makes it ideal for weight reduction in transportation equipment such as automotives, railway vehicles, and aircraft—contributing to improved energy efficiency.

- Its tensile strength can be adjusted depending on the alloy type and temper, allowing for the right material to be selected based on the application.

- A naturally occurring oxide film forms on the surface of aluminum, providing excellent corrosion resistance. This protective layer prevents red rust commonly found on steel.

Lightweight, Strong, and Corrosion-Resistant

| Property | Use Cases | Typical Applications |

|---|---|---|

| Lightweight | Aluminum has a specific gravity of 2.7—about one-third that of iron (7.8) or copper (8.9). | Automotives, railway vehicles, aircraft, ships, and more |

| Strong | Aluminum has a high specific strength (strength per unit weight). Its strength can be increased by alloying pure aluminum with magnesium, manganese, copper, silicon, zinc, or by rolling and other processing and heat treatment. | Structural components for transportation and construction |

| Excellent corrosion resistance | In the air, aluminum forms a dense and stable oxide film, which naturally protects against corrosion. | Construction, automotives, shipbuilding, and marine use |

| Excellent electrical conductivity | The electrical conductivity is about of 60% that of copper, but its specific weight is one-third that of copper. This allows it to carry twice the current per unit weight. | High-voltage transmission lines, conductors (sheets, tubes), etc. |

| High thermal conductivity | Approximately three times that of steel. | HVAC systems, heat exchangers, beverage cans, etc. |

| Non-magnetic | Aluminum is non-magnetic and unaffected by magnetic fields. | Measuring instruments, electronic medical devices, mechatronics equipment, etc. |

Contact Us

You can reach us by clicking the inquiry button.