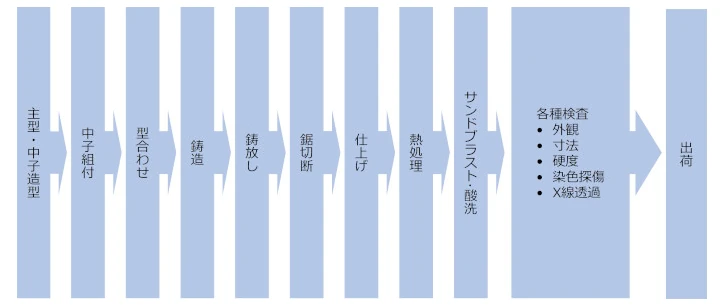

Manufacturing Process for Aluminum Cast Products

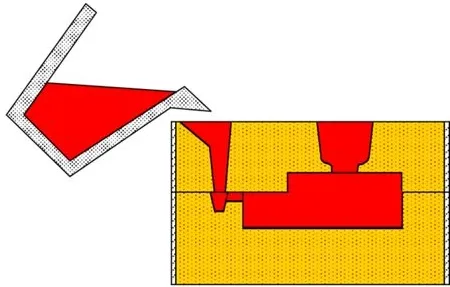

Overview of the Sand Mold Casting Process

Typical Manufacturing Process

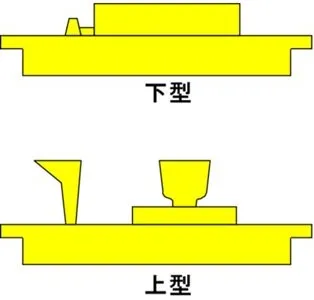

- (1) Wooden Mold Fabrication

A wooden or resin master mold is first created for making the sand mold.

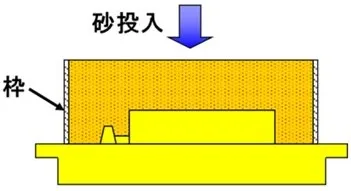

- (2) Sand Mold Formation

Sand is packed around the mold created in the previous step to form the sand mold.

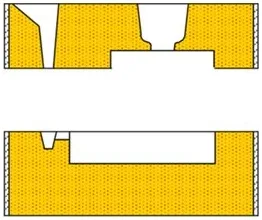

- (3) Assembly and Alignment

The individual sand molds are assembled and fitted together to form the full mold.

- (4) Pouring

Molten metal is poured into the assembled sand mold to form the desired shape.

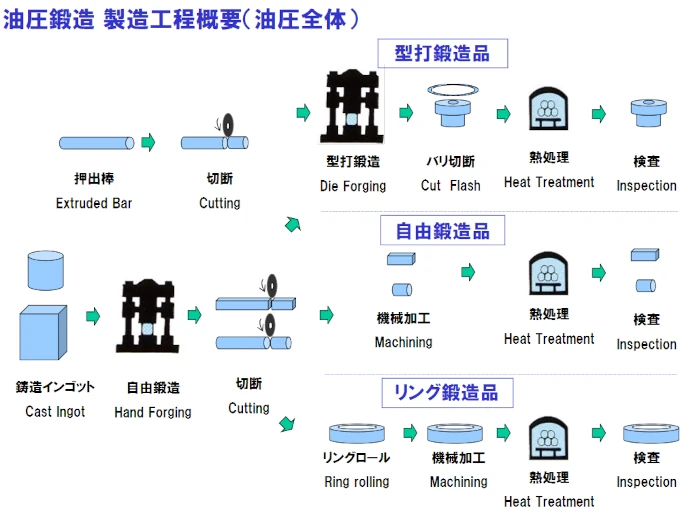

Overview of Forging Process(using Hydraulic press)

Typical Manufacturing Process

Closed-Die Forged Products

- (1) Cutting

The material is cut to the specified size.

- (2) Die Forging

Die forging:

A forging method in which a die with a product-shaped cavity is used to form the material.

This process yields consistent quality and dimensions, and minimizes additional machining.

- (3) Deburring

Excess material (flash) produced during forging is trimmed off.

- (4) Heat Treatment

The part undergoes a specific heat treatment process to achieve the desired product characteristics.

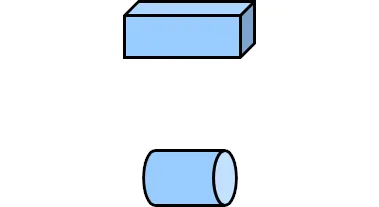

Hand Forged Products

- (1) Hand Forging

Hand forging:

This forging method begins by shaping the material into a square on a flat anvil, then forming it into a cylindrical or block shape to meet the required dimensions.

Since no die is required, it is suitable for large parts or low-volume production.

- (2) Cutting

The material is cut to the specified size.

- (3) Machining

We operate our own in-house machining processes, using machine tools to cut and grind each workpiece.

- (4) Heat Treatment

The part undergoes a specific heat treatment process to achieve the desired product characteristics.

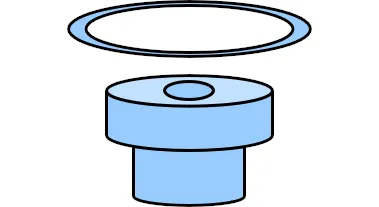

Ring Forged Products

- (1) Hand Forging

Hand forging:

This forging method begins by shaping the material into a square on a flat anvil, then forming it into a cylindrical or block shape to meet the required dimensions.

Since no die is required, it is suitable for large or low-volume parts.

- (2) Cutting

The material is cut to the specified size.

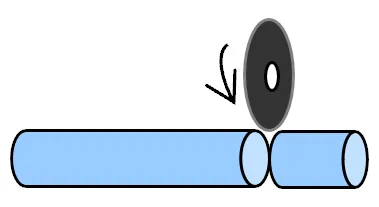

- (3) Ring Rolling (Ring Forging)

A type of hand forging in which a hole is formed in the center of a cylinder, and then the material is expanded outward.

Because large tubular shapes can be formed without drilling a large hole in the center, this reduces material losses both during manufacturing and later when customers would otherwise need to bore and cut the material.

- (4) Machining

We operate our own in-house machining processes, using to machine tools to cut and grind each workpiece.

- (5) Heat Treatment

The part undergoes a specific heat treatment process to achieve the desired product characteristics.

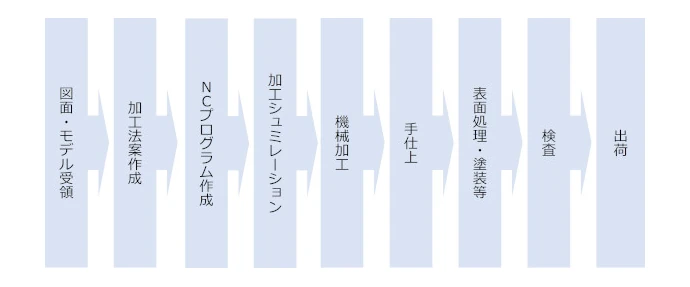

Overview of the Machining Process

- (1) NC Program Creation and Simulation

NC programs are created and verified through self-checks and double checking. Product, jig, and machine tool models are used to simulate the machining process on a PC.

- (2) Machining

Cutting tools are used to cut and grind the part. We operate multiple machine tools, each suited to different types of operations.

- (3) Hand Finishing

Certain products are finished by hand using tools.

(Examples: chamfering, polishing, buffing, scratch correction, welding, and cleaning)

- (4) Inspection

Dimensional inspection, appearance checks, pressure resistance testing, and leak testing are conducted.

- (5) Shipping

After packaging, products are shipped to the customer.

Contact Us

You can reach us by clicking the inquiry button.