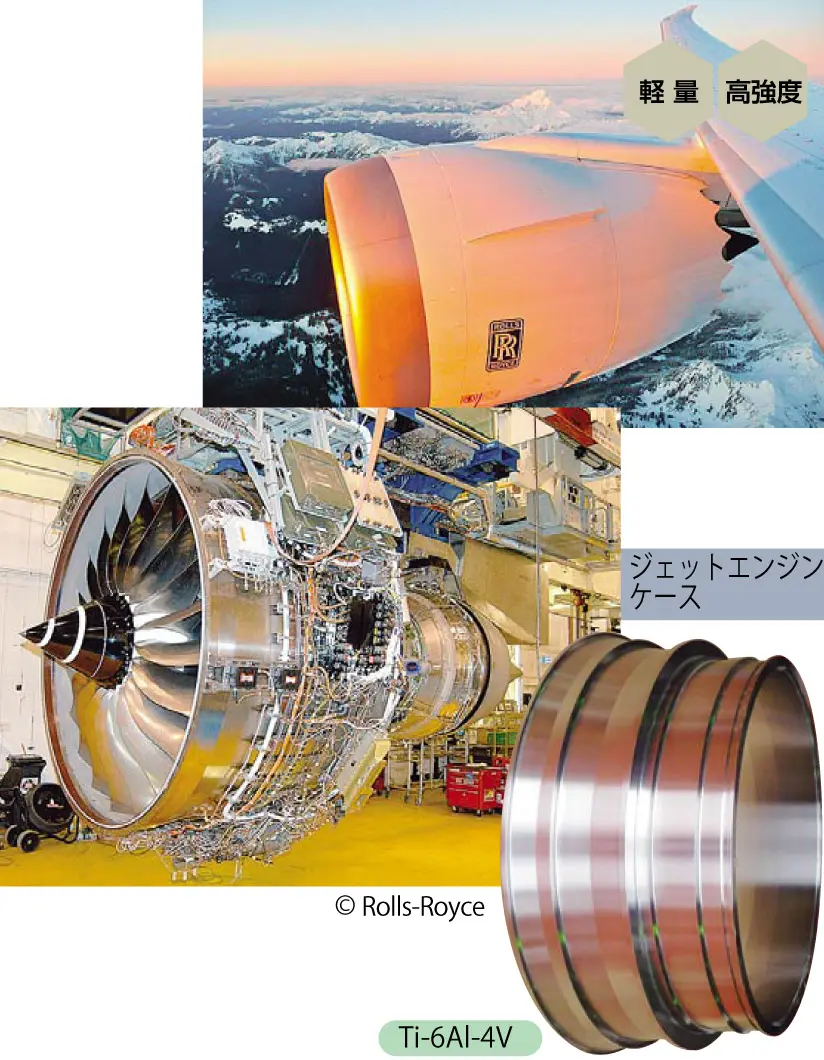

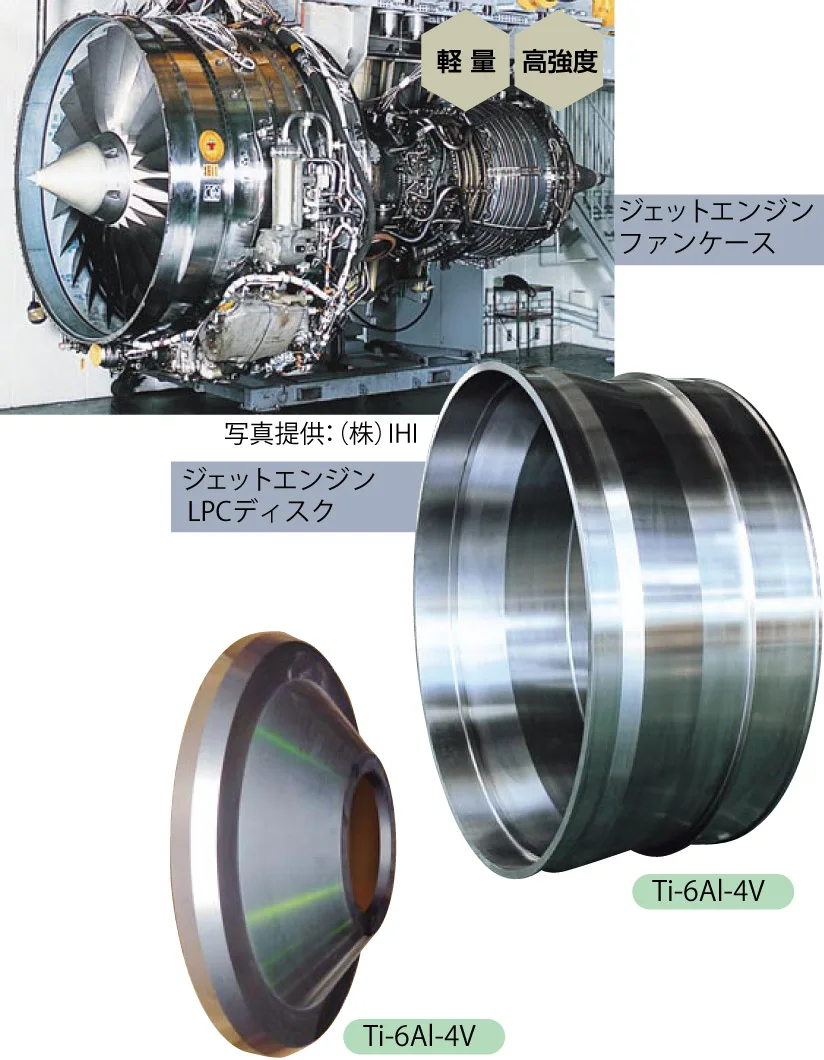

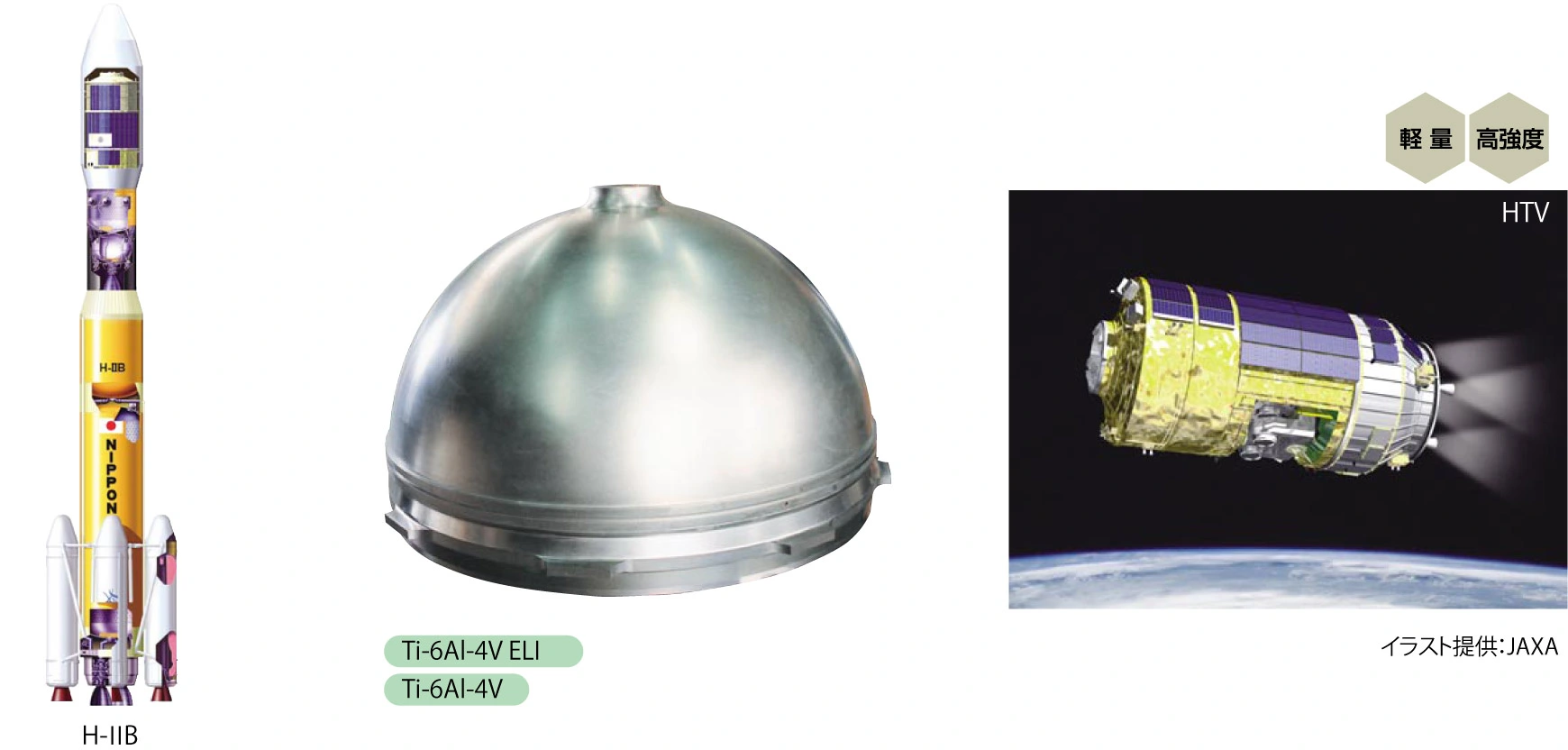

Titanium Alloys for Forged Products for Aircraft Use

Features

The most commonly used titanium alloy for aircraft is Ti-6Al-4V (abbreviated as Ti-64). Ti-64 is most versatile titanium alloy that offers a good balance of mechanical properties such as tensile strength and fracture toughness. It also has a solid technical database due to a proven track record in the aircraft industry. It is used for a wide range of parts, including aircraft structural components, and parts with a heat resistance of up to approximately 300°C, such as jet engine fan rotors and parts near the low-pressure compressor.

Applicable products

| Classification | Nominal composition | Kobe Steel standards | Other standards (These standards differ slightly from Kobe Steel standards) |

|---|---|---|---|

| Titanium alloys | Ti-6Al-4V | KS6-4 | JIS Class 60 ASTM G5 and F5 AMS4911 and 4928 |

| KS6-4ELI | JIS Class 60E AMS4907 and 4930 |

||

| Ti-4.5Al-2Mo-1.6V-0.5Fe-0.3Si-0.03C | KSTI-9(Ti-9) | ASTM G35 | |

| Ti-4.5Al-3.5Cr-0.5Fe-0.2C | KS EL-F | ||

| Ti-6Al-2Sn-4Zr-6Mo | KS6-2-4-6 | AMS4981 |

Applicarions

- Aircraft parts

- Connection rods

- Valve spring retainers

- Structural parts

- Golf club heads, etc.

Aircraft and aerospace

Manufacturing process video

Specifications and available manufacturing scope

Contact Us

You can reach us by clicking the inquiry button.