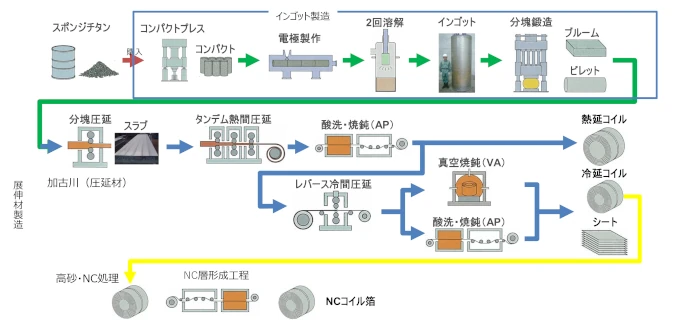

Rolling Process for Titanium

Overview of the Rolling Process

Rolling is a forming method in which titanium is passed between two or more rotating rolls under high pressure to elongate the material.

Typical Manufacturing Process

Melting and Bloom/Billet Casting of Titanium

- (1) Compacting of titanium sponge

Titanium sponge, the raw material, is compressed using a press.

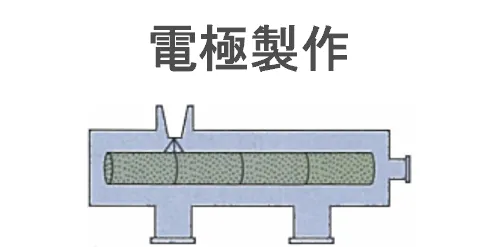

- (2) Electrode formation

The compacted sponge is welded to form an electrode.

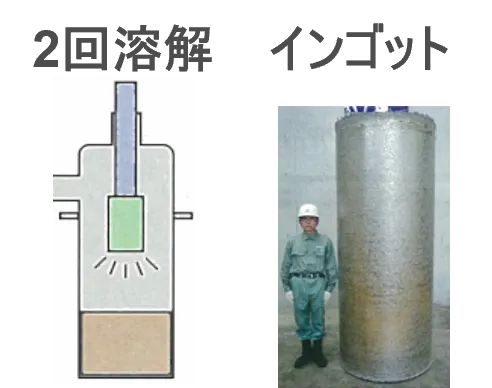

- (3) Melting and ingot casting

The electrode is cast into an ingot using an electrode arc melting process.

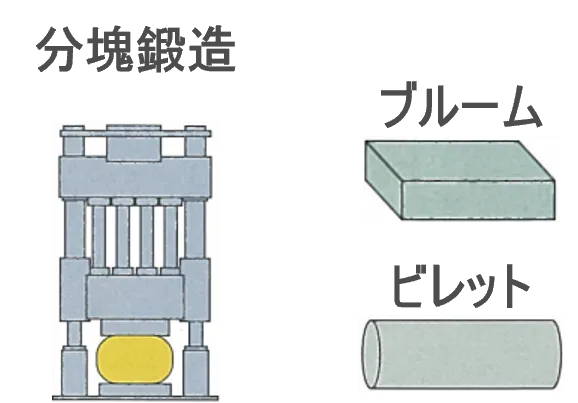

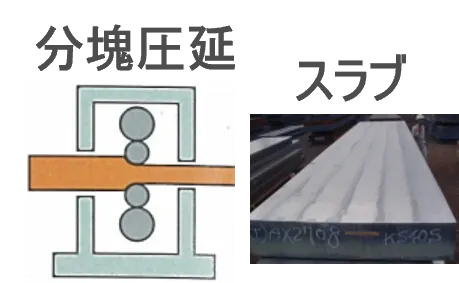

- (4) Bloom/billet forging

The cast ingot is pressed into bloom or billet form using a press.

Rolling, Annealing, and Processing (Hot-Rolled Coil)

- (5) Rolling

The titanium is hot-rolled above its recrystallization temperature to achieve the required sheet thickness.

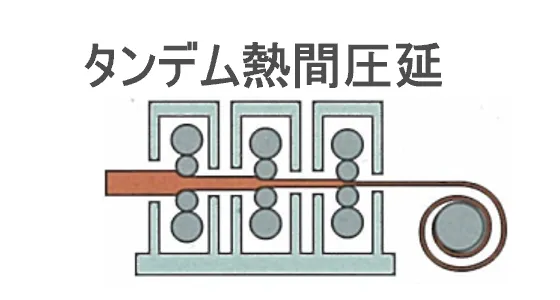

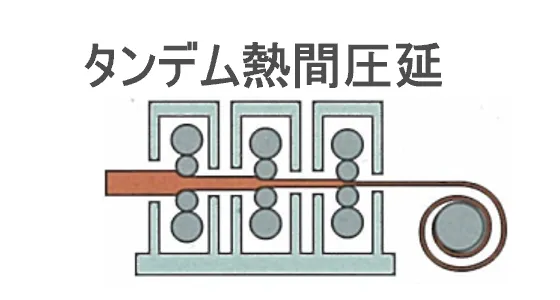

- (6) Tandem hot rolling

The titanium is rolled in stages at high temperature above its recrystallization temperature to achieve the required sheet thickness.

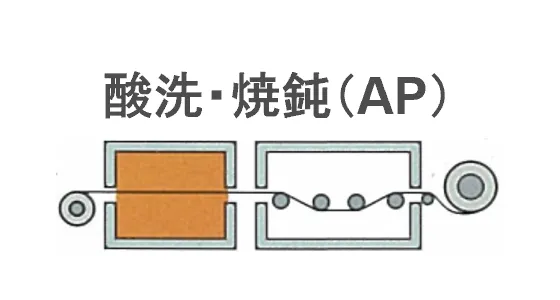

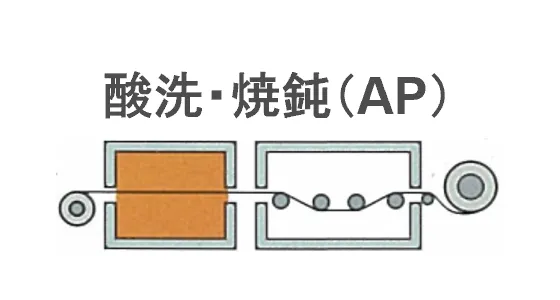

- (7) Pickling and annealing (AP)

The material is annealed to impart the required mechanical properties, while removing oils and other contaminants.

- (8) Completion

The material is processed to its final shape and shipped.

Rolling, Annealing, and Processing (Cold-Rolled Coil)

- (5) Rolling

The titanium is hot-rolled above its recrystallization temperature to achieve the required sheet thickness.

- (6) Tandem hot rolling

The titanium is rolled in stages at high temperature above its recrystallization temperature to achieve the required sheet thickness.

- (7) Pickling and annealing (AP)

The material is annealed to impart the required mechanical properties, while removing oils and other contaminants.

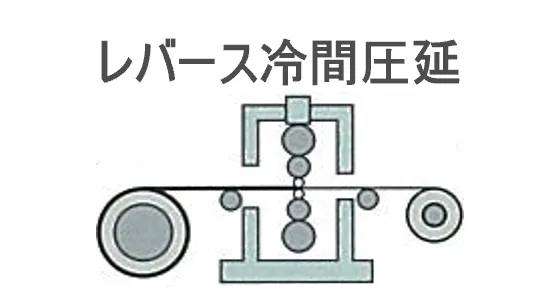

- (8) Reversible cold rolling

Rolling is performed at room temperature.

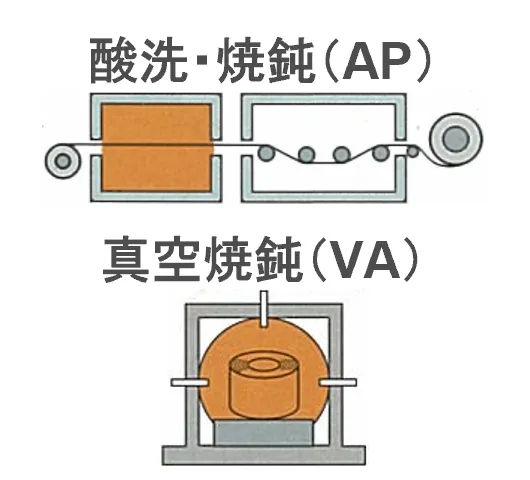

- (9) Pickling and annealing (AP) / Vacuum annealing (VA)

Continuous pickling and annealing are carried out.

Heat treatment is performed in a vacuum.

- (10) Completion

Produces coils that are thinner and dimensionally more precise than those made by hot rolling.

The cold-rolled coil is then cut into sheet form.

Contact Us

You can reach us by clicking the inquiry button.