Kobe Steel’s Titanium

Pioneering Titanium in Japan

Kobe Steel was the first company in Japan to begin research and development on titanium in 1949, and has the longest history with titanium than any other company.

With over 60 years of experience in titanium, we have supported the growth of industries across a wide range of fields.

With over 60 years of experience in titanium, we have supported the growth of industries across a wide range of fields.

Japan’s Only Fully Integrated Titanium Manufacturer

Being an integrated manufacturer that handles everything from titanium melting to final product enables Kobe Steel to provide consistent quality design and quality control.

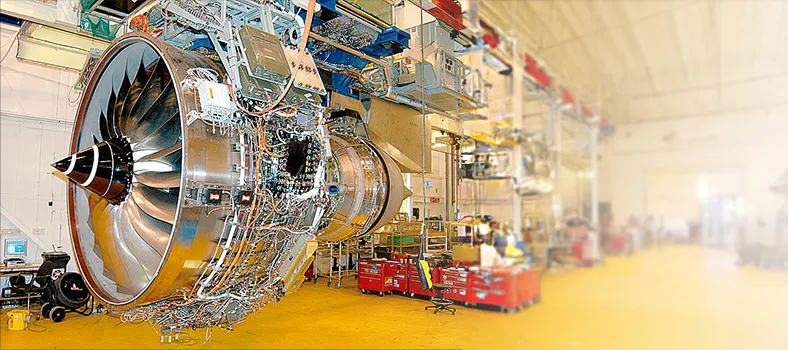

Trusted, High-Quality Titanium for Aircraft

Kobe Steel’s advanced technical expertise and proven track record in titanium forgings—along with our fully integrated manufacturing system—have earned us numerous supplier certifications from aircraft and engine manufacturers in Japan and around the world.

Wide Range of Product Grades

We offer a broad lineup of materials, from commercially pure titanium to titanium alloys, and support a wide variety of product forms—from sheets to forgings.

World-Class In-House Facilities for Titanium Production

Our dedicated titanium facilities, made possible by our status as titanium pioneers, continue to produce products of the highest quality.

Our Dedicated Titanium Production Facilities

Charge-type melting furnace

Continuous annealing and pickling line

Vacuum annealing furnace

Ring rolling mill

8,000-ton press

Tandem hot rolling mill

Commitment to New Materials and Technologies

We develop materials, joining technologies, and functional surface treatments tailored to diverse applications and customer needs.

Materials and Technologies Developed by Kobe Steel

| Category | Name | Composition | Key Features |

|---|---|---|---|

| Commercially pure titanium | Titanium for building materials | Commercially pure titanium | Resistant to pocket-shape waves, low gloss, and discoloration over time |

| Titanium for forming applications | Commercially Pure Titanium | Customizable material properties and surface quality based on forming requirements | |

| Titanium Alloys | KS100、KS120 | Ti-Fe-O-(Si) | Excellent scratch resistance, polishability; higher strength than Ti-3Al-2.5V using cost-effective alloying elements |

| AKOT | Ti-Ni-Pd-Ru-Cr | Exceptional corrosion resistance | |

| KSTI-5TA | ← | Resistant to high-temperature and high concentration nitric acid | |

| KSTI-1.5AL | ← | Heat resistance, hydrogen absorption resistance, and formability equivalent to commercially pure titanium | |

| KSTI-1.2ASNEX | Ti-Al-Si-Nb | Oxidation resistance and formability equivalent to commercially pure titanium | |

| KSTI-0.9SA | Ti-Al-Si | Oxidation resistance and formability equivalent to commercially pure titanium | |

| KSTI-9 | Ti-Al-Mo-V-Fe-Si-C | Cold rolling possible; properties equivalent to Ti-6Al-4V | |

| KS EL-F | Ti-Al-Cr-Fe-C | Hot forgeability and machinability equivalent to commercially pure titanium | |

| KS5-3-1C | Ti-Al-Cr-Fe-C | Hot forgeability and machinability equivalent to commercially pure titanium | |

| KS16-4-3-3 | Ti-V-Sn-Al-Nb | Excellent cold workability | |

| KS15-5-3 | Ti-Mo-Zr-Al | Ultra-high strength and exceptional corrosion resistance | |

| KS15-0-3 | Ti-Mo-Al | Ultra-low Young’s modulus | |

| Joining Technology | Dissimilar metal welding technology | - | Enables welding of titanium to other metals (steel, stainless steel, etc.) |

| Surface Treatments | PdO/TiO2 treatment | - | Exceptional corrosion resistance |

| KENI FINE | - | Antibacterial properties | |

| Inorganic clear coating for titanium | - | Resistant to discoloration over time, easy to clean, scratch-resistant, and fingerprint-resistant |

Awards and Recognitions

The technological developments of Kobe Steel, a pioneer of titanium development in Japan, have played a key role in today’s global expansion of titanium applications.

Our technological advancements have been widely recognized, earning numerous awards in various areas.

| Technology Development | Award Details | |

|---|---|---|

| 2023 |

|

|

| 2022 |

|

|

| 2021 |

|

|

| 2021 |

|

|

| 2003 |

|

|

| 2000 |

|

|

| 1997 |

|

|

| 1996 |

|

|

| 1995 |

|

|

| 1991 |

|

|

| 1986 1988 |

|

|

| 1982 |

|

|

| 1974 |

|

|

| 1963 |

|

|

| 1959 |

|

|

| 1958 |

|

|

| 1956 |

|

|

User Support System

With expertise in material design and processing technologies built up over the years, we support product development across a wide range of applications—from golf clubs to jet engine components. Our knowledge and experience help enable faster, more cost-effective development.

Contact Us

You can reach us by clicking the inquiry button.