MAGMEL™ for Magnetic Applications

MAGMEL™ is soft magnetic iron powder for compact magnetic core with insulating layer on its surface.

It reduces eddy current loss and produces parts with low iron loss.

The compactability of the powder is superior and it will give high magnetic flux density.

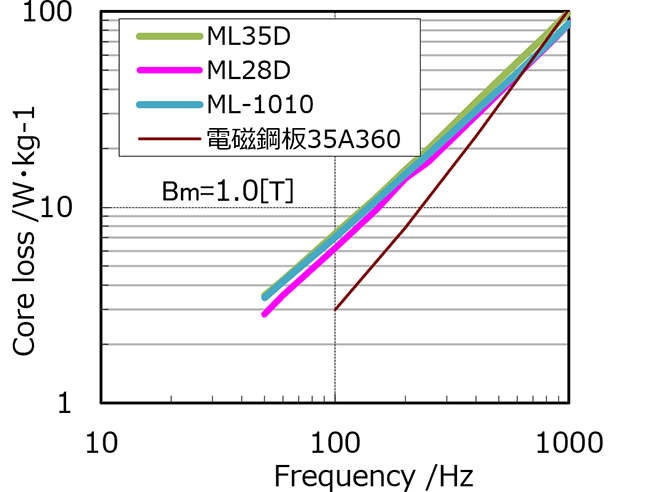

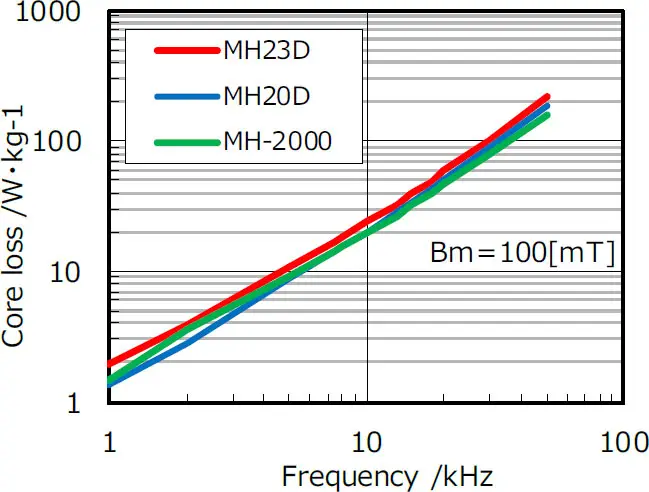

We have ML series for low frequency and MH series for high frequency.

Features

- Low iron loss and high efficiency

As a high heat-resistant insulated coating is formed on the steel powder, high-temperature magnetic annealing of a compacted powder is possible.

In addition to alleviating compacting deformation due to annealing, iron loss is reduced by controlling steel powder particle size and structure.

Additionally, by insulating the spaces between particles, eddy current loss at high frequency ranges can be reduced, making it possible to handle high-speed rotation and harmonics. - Support for three-dimensional design

As it is magnetically isotropic, three-dimensional circuit design can be supported.

Flexible circuit design is expected to enable lighter and more compact components. - Caters to a wide range of needs

We offer grades for die-lubricated compacting and internally-lubricated compacting, catering to diverse needs.

For die-lubricated compacting: High magnetic flux density and high strength

Internally-lubricated compacting: high productivity and complex shapes

Magnetic Properties of Soft Magnetic Iron Powder

List of Properties

ML-1000 and MH-2000 are for internally-lubricated compacting, while other types are for die-lubricated compacting.

| Application | Steel grade name | Density (g/cm3) |

Magnetic Flux Density B10kA/m (T) |

Maximum Relative Permeability | Coercive Force (A/m) | Core Loss*1 (W/kg) | Transverse Rupture Strength (MPa) |

|---|---|---|---|---|---|---|---|

| Low frequency | ML35D | 7.62 | 1.66 | 526 | 154 | 34 | 84 |

| ML28D | 7.72 | 1.70 | 545 | 128 | 29 | 70 | |

| ML-1010※2 | 7.41 | 1.51 | 325 | 157 | 31 | 48 | |

| High frequency | MH23D | 7.49 | 1.50 | 270 | 253 | 22 | 89 |

| MH20D | 7.44 | 1.46 | 224 | 224 | 20 | 77 | |

| MH-2000*3 | 7.27 | 1.29 | 187 | 230 | 20 | 51 |

Annealing: 600℃×30min (N2GAS)

Die Lubrication Compacting:1176MPa,130℃

Iron loss

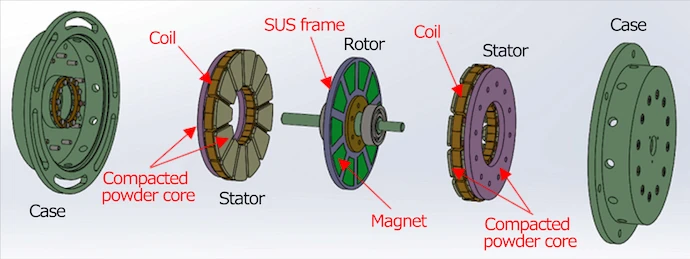

Examples of Soft Magnetic Iron Powder Applications

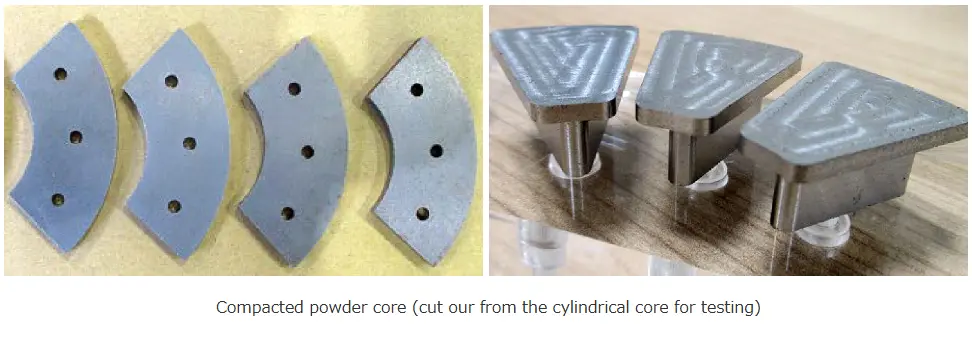

There are examples of application in reactor cores and in-wheel motors.

The powder is suited to motors with three-dimensional magnetic circuits such as axial gap motors.

We also provide compacted powder cores (materials for cutting or processed pieces for a designed shape) for testing purposes.

Contact Us

You can reach us by clicking the inquiry button.