Manufacturing Process for Aluminum Forged Products

Overview of the Aluminum Forging Process

- An integrated mass production line from continuous casting bar to forging, heat treatment, and inspection

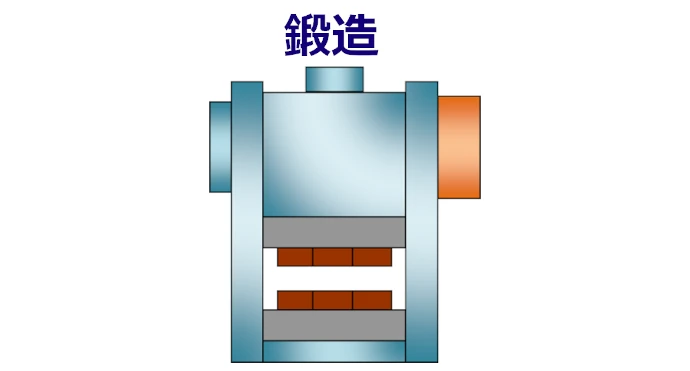

- Single-heat continuous forging using a multi-die layout on a massive heavy-duty 6,300-ton mechanical forging press

Typical Manufacturing Process

- (1) Melting and Casting

High-strength aluminum alloy is melted and cast into billets using a continuous billet caster.

- (2) Homogenization

To eliminate micro-segregation that occurs during solidification, the billets undergo homogenization treatment.

- (3) Forging

Medium- to large-sized forged aluminum products are efficiently produced through single-heat continuous forging using a multi-die layout on a large 6,300-ton mechanical forging press.

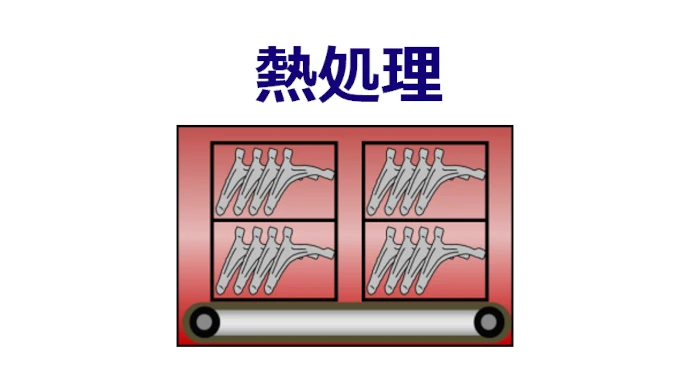

- (4) Heat Treatment

Solution heat treatment, quenching, and aging are applied to increase the strength of the forged aluminum products.

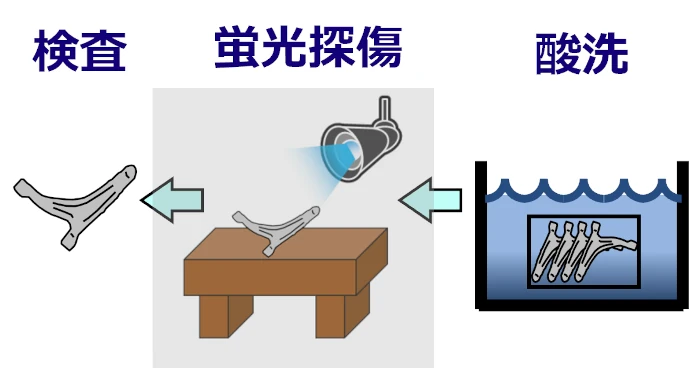

- (5) Inspection

After pickling, fluorescent penetrant inspection is conducted to ensure only high-quality aluminum forged products are shipped.

Contact Us

You can reach us by clicking the inquiry button.