Kobe Steel’s Copper

Production of Original Alloys Offering High Functionality and Quality

With the advancement of CASE technologies, demand for copper continues to grow.

At Kobe Steel, we manufacture original alloys with high performance and high quality, and provide surface treatment technologies.

At Kobe Steel, we manufacture original alloys with high performance and high quality, and provide surface treatment technologies.

World-Class

In-House Facilities for Copper Production

In-House Facilities for Copper Production

Hot Rolling Mill

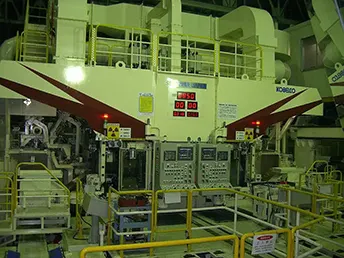

4-high Cold Rolling Mill (No. 10 Rolling Mill)

20-high Cold Rolling Mill (No. 1 Rolling Mill)

Annealing Furnace

Continuous Annealing/Polishing Line

Slitter Line

Commitment to New Materials and Technologies

We meet customer needs through material development and surface treatment technologies tailored to a wide range of applications.

Alloys Developed by Kobe Steel (Partial List)

| Alloy Name | Chemical Composition (wt%) |

Features | Applications |

|---|---|---|---|

| KFC® | Cu-0.1Fe-0.03P |

|

Lead frames for transistors and LEDs, IGBT heat sinks, heat spreaders, radiation plates for BGAs, internal radiation frames, etc. |

| SuperKFC® | Cu-0.3Fe-0.1P |

|

Lead frames for QFP and QFN packages and LEDs, internal heat dissipation frames, etc. |

| KLF®-5 | Cu-2.0Sn-0.1Fe-0.03P |

|

General-purpose terminals and small terminals for automotive use; small terminals and connectors for consumer and industrial equipment |

| KLF®-170 | Cu-0.7Ni-0.13P-0.1Fe-0.1Zn |

|

Lead frames for QFP and QFN packages, internal heat dissipation frames, etc. |

| CAC®60 | Cu-1.8Ni-0.4Si-1.1Zn-0.1Sn |

|

Small automotive wire harness terminals, specialized terminals for consumer and industrial equipment, internal heat dissipation frames, etc. |

| CAC®5 | Cu-0.8Ni-1.2Sn-0.07P |

|

Small automotive wire harness terminals, specialized terminals for consumer and industrial equipment, lead frames for mini-mold transistors, etc. |

| CAC®75 | Cu-2.5Ni-0.55Si-1.0Zn-0.2Sn |

|

Small automotive wire harness terminals, specialized terminals for consumer and industrial equipment, etc. |

Awards

| Technology Development | Award Details | |

|---|---|---|

| 2024 |

|

|

Contact Us

You can reach us by clicking the inquiry button.