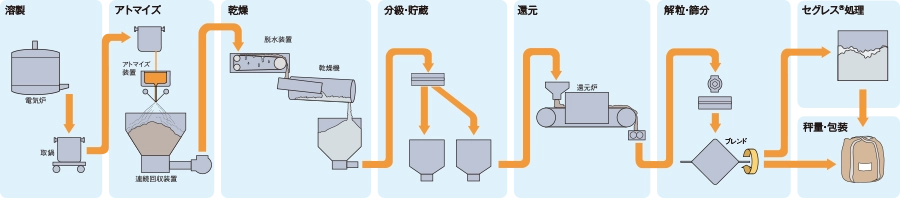

Steel Powder Production Process

Overview of Steel Powder Production Process

Typical Production Process

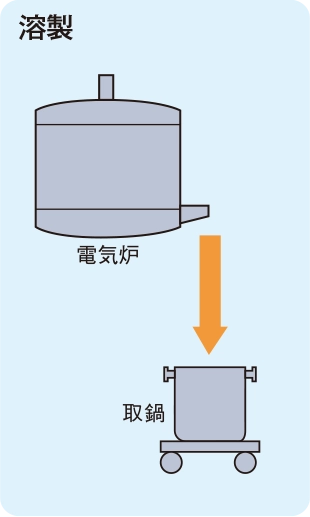

- (1) Melting

Raw materials are melted in a fully enclosed, large-capacity DC electric furnace with thorough soundproofing and dust control.

The addition of secondary materials and temperature control are fully automated, ensuring molten steel with consistent composition.

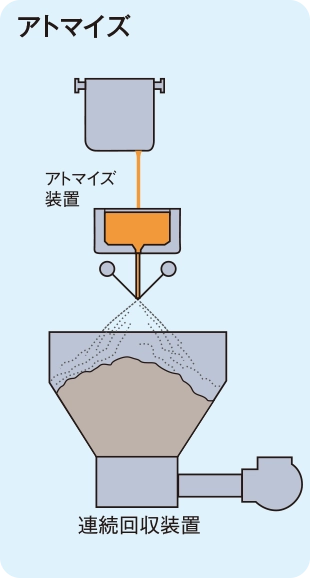

- (2) Atomization

Molten steel is converted into powder using a V-Jet water atomization system.

The steel is poured from a ladle into a tundish, where it flows through a nozzle to be struck by high-pressure water jets, breaking it into fine particles.

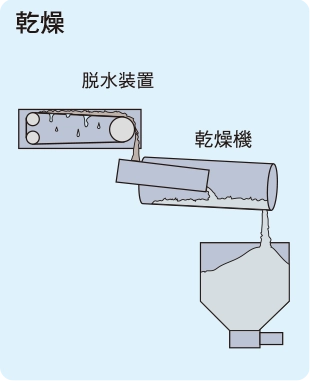

- (3) Drying

The fine steel powder is dehydrated with a dewatering unit, and then dried in a dryer.

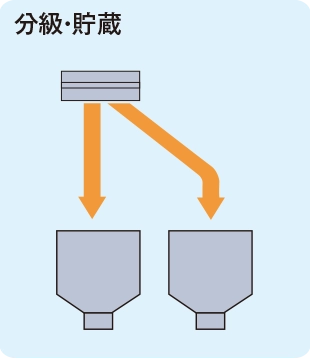

- (4) Classifying and storage

After drying, the powder is sieved by particle size and temporarily stored in separate containers according to size classification.

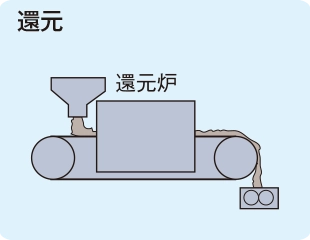

- (5) Reduction

A reduction furnace removes oxide films from the powder surface.

Under tightly controlled temperature and atmospheric conditions—managed by multiple sensors—the powder is both deoxidized and annealed.

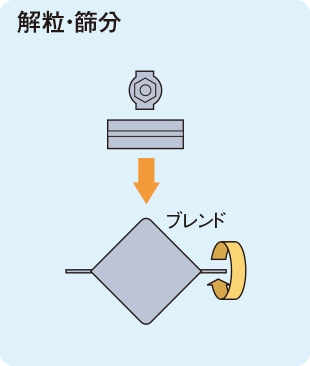

- (6) Disintegration and sieving

The reduced powder, which may be caked together, is crushed in a disintegrator and re-sieved to separate it by particle size. It is then blended to produce powder with uniform apparent density and consistent particle size distribution.

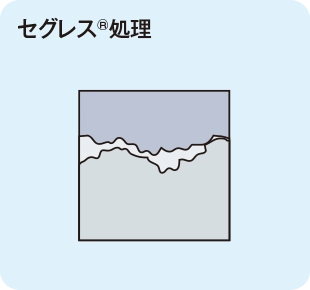

- (7) SEGLESS™ Process

Additives such as graphite powder are blended with the steel powder to produce premixed powder products that support improved work environments and labor efficiency.

SEGLESS™ is a specially treated premix in which graphite powder is bonded to steel powder particles to prevent segregation, resulting in a uniformly mixed product.

- (8) Packaging

Finished steel powder products are weighted and packed into flexible containers at the Steel Powder Plant before being shipped.

Contact Us

You can reach us by clicking the inquiry button.