High Strength Steel Powder for Sintered Gears

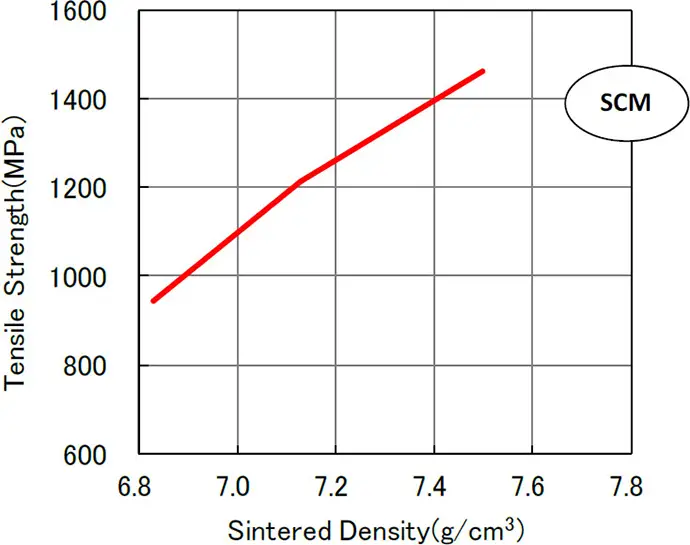

Achieves high strength equivalent to or greater than cast steel gears

46F4H

Features

- No reduction in strength due to oxidization

As it contains no easily oxidizable elements such as Cr, there are no concerns over oxidization during sintering or heat treatment, and high strength can be obtained even through RX gas carburization.

| Alloy components | Ni | Mo |

|---|---|---|

| Composition | 0.5% | 1.0% |

| Approach to components | Ensuring toughness | Improving hardenability |

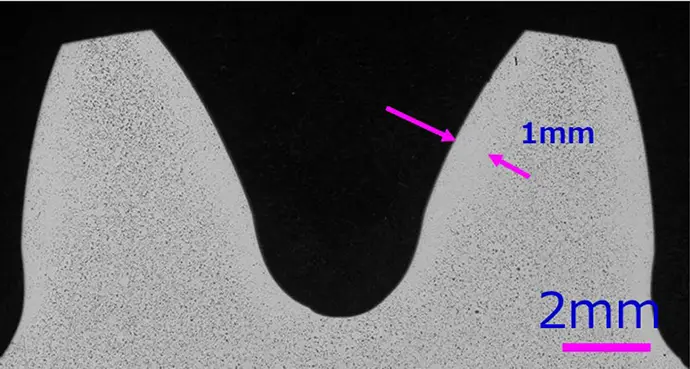

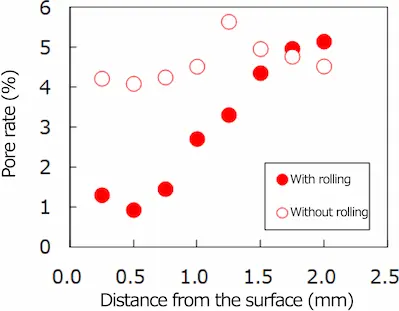

- Achieves high strength through rolling

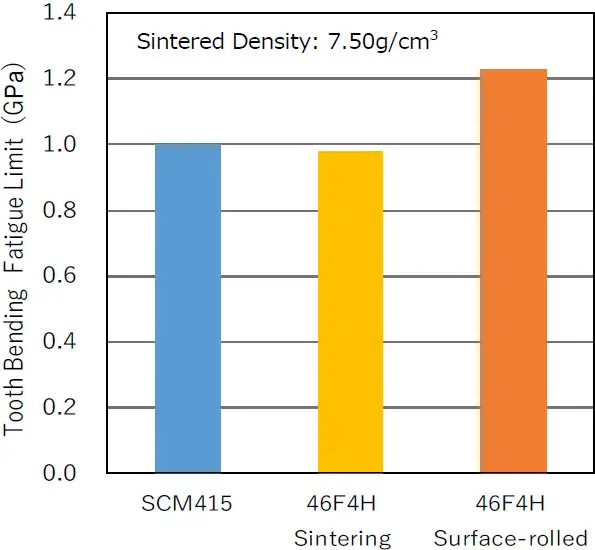

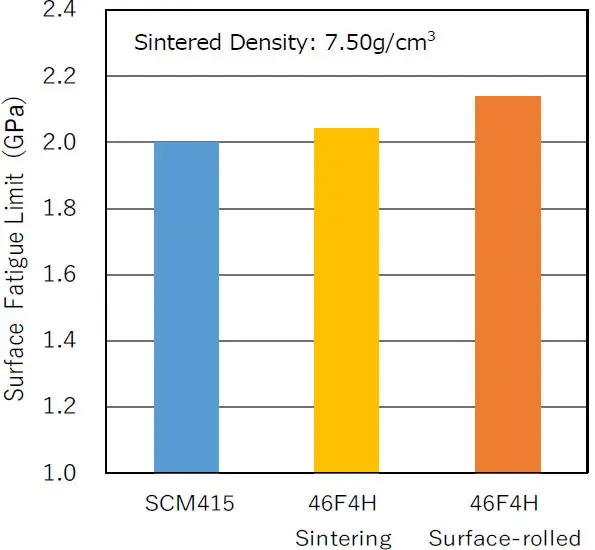

Surface rolling allows pores to be reduced, producing strength that is equal to or greater than cast steel gears.

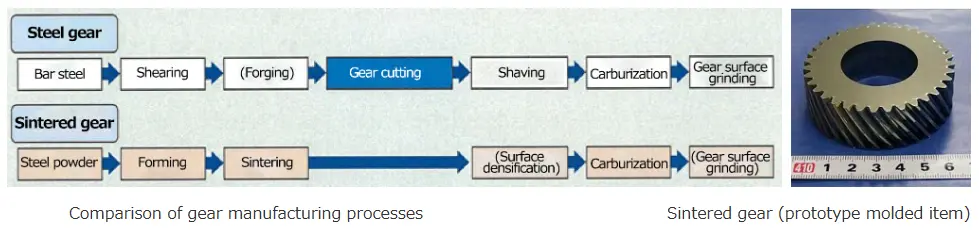

- High material yield and ability to shorten construction schedules

As no gear cutting process is required, the material yield is higher than with cast steel gears, and productivity improvements can also be expected thanks to be process being skipped.

Representative Characteristics

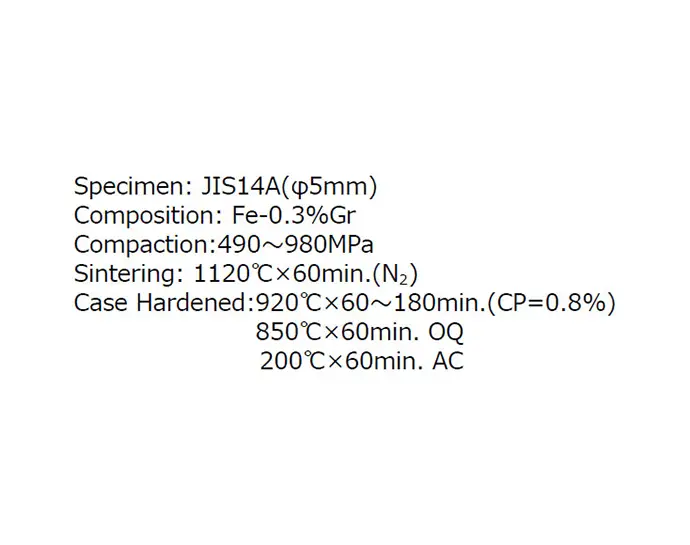

Tensile Strength

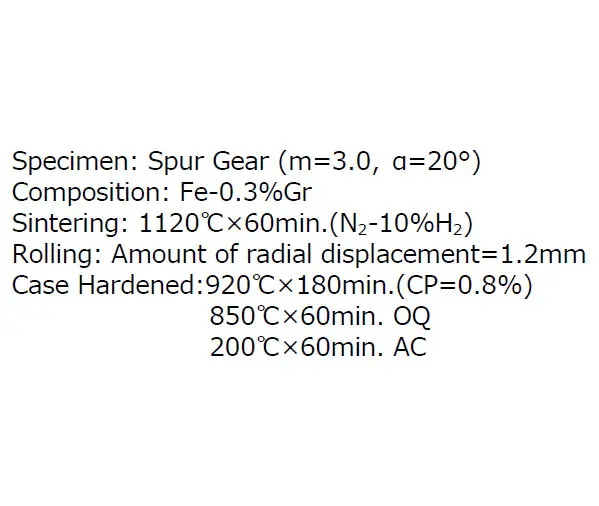

Gear Fatigue Strength

Applications

Automotive, motorcycle, industrial machinery, office equipment, and electrical equipment parts

Contact Us

You can reach us by clicking the inquiry button.