High-Compressibility SEGLESS™ KP Series

SEGLESS™ with higher compressibility and lubricity than conventional mixed powders

Features

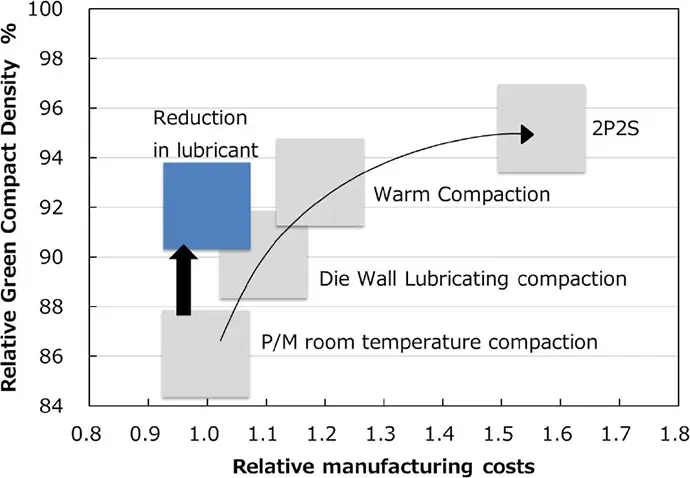

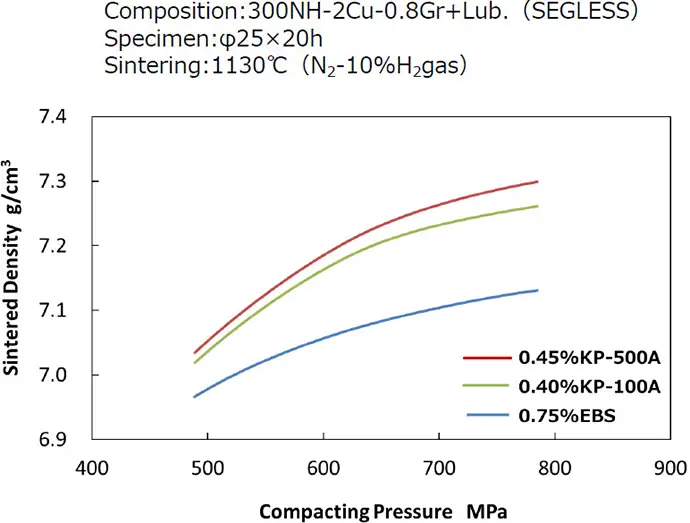

With the growing demand for higher density and strength in sintered parts, the high-density SEGLESS™ KP Series was developed by blending a high-density lubricant that enables the density of compacted powder to be increased at low cost, unlike conventional densification processes (warm forming, 2P2S).

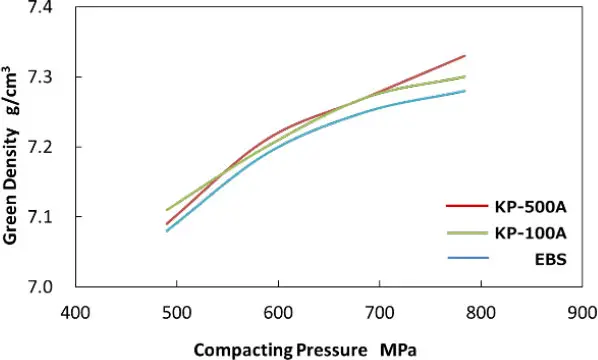

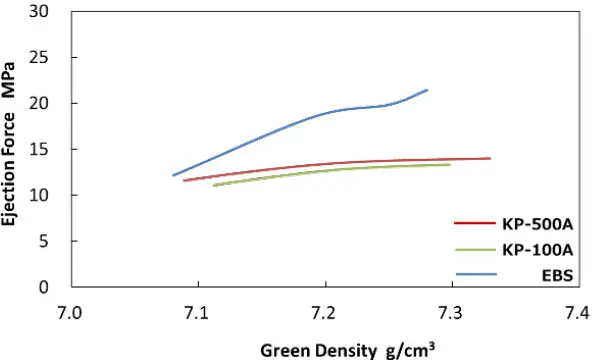

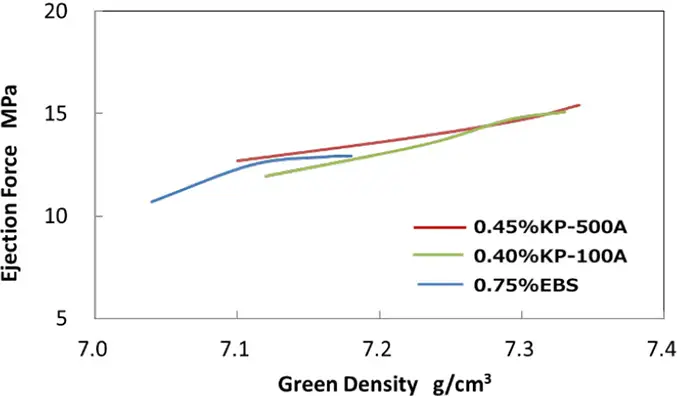

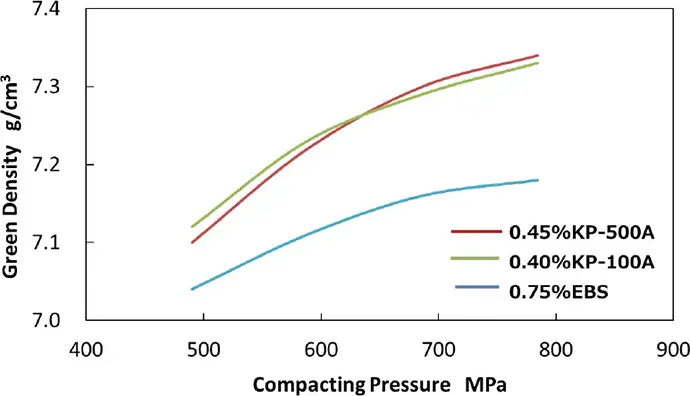

- High lubricity / high compressibility

Due to the high lubricity, the load placed on a die is reduced, extending its lifespan.

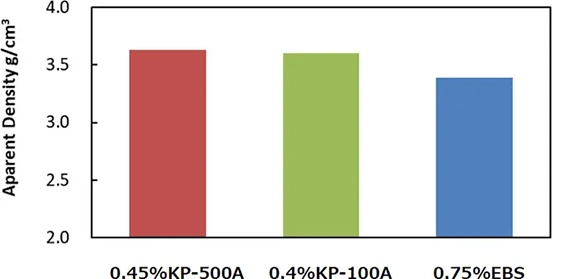

In addition, as a high-density compacted powder can be achieved by reducing the amount of lubricant additive, forming pressure can be suppressed more than previously, enabling press downsizing. - High degradability

As the lubricant has excellent degradability, staining or flaws on the surface of a sintered body can be prevented.

Densification process and manufacturing costs

Lubricant: Comparison with same additive amount

Lubricant: Comparison at recommended additive amounts for each lubricant

Applications

Automotive, motorcycle, industrial machinery, office equipment, and electrical equipment parts

Contact Us

You can reach us by clicking the inquiry button.