Prevents Segregation of Graphite Steel Powder SEGLESS™

Prevents Segregation of Graphite Steel Powder SEGLESS™

Features

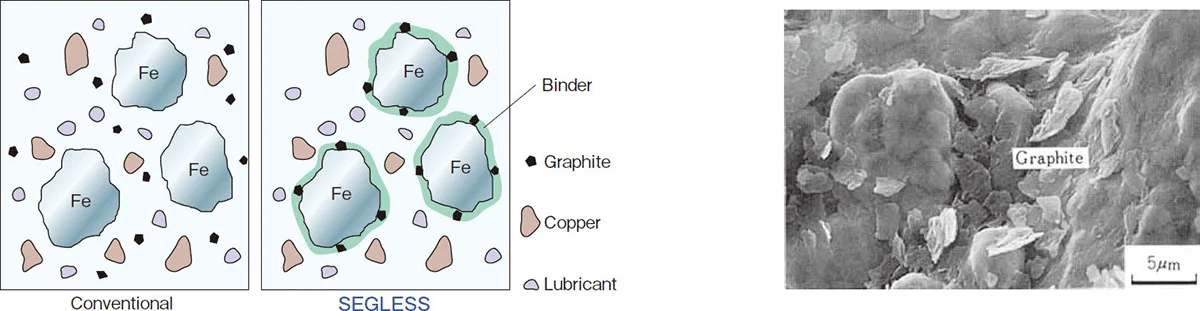

SEGLESS™ is a mixed powder that prevents the segregation of graphite powder.

This product not only improves the working environment by suppressing dust from graphite powder, but it also ensures stable quality of manufactured parts by minimizing variability caused by graphite segregation.

By using the high-compressibility SEGLESS™(KP series) or high-machinability SEGLESS™(KS series) developed by Kobe Steel, even higher performance can be achieved.

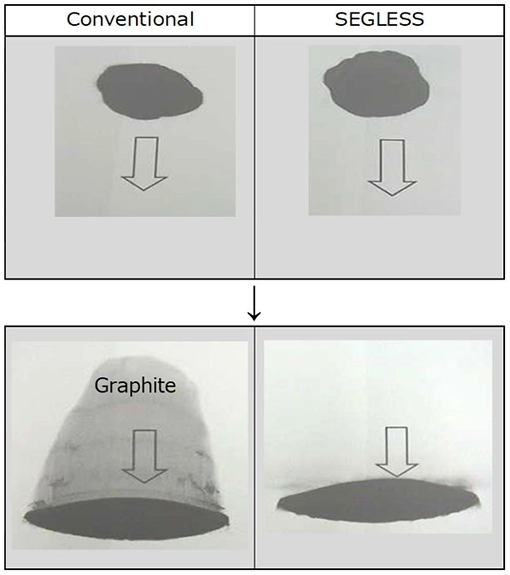

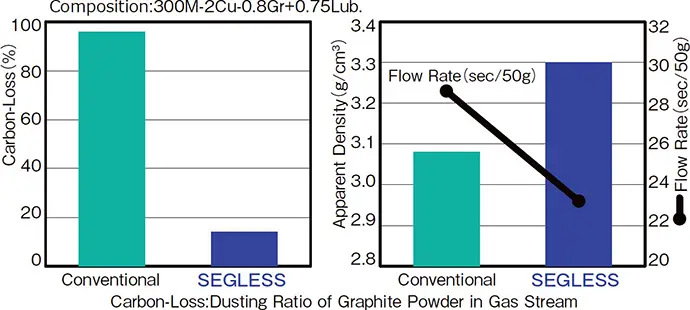

- Suppresses dust generation

Suppresses dust from graphite powder, contributing to an improved working environment.

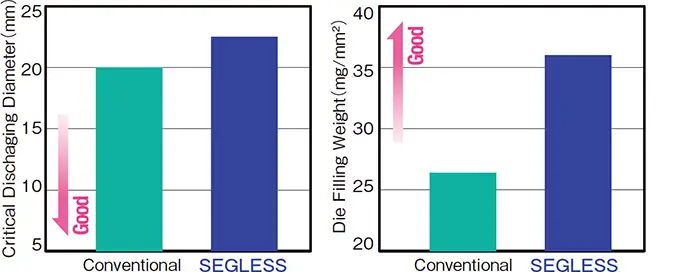

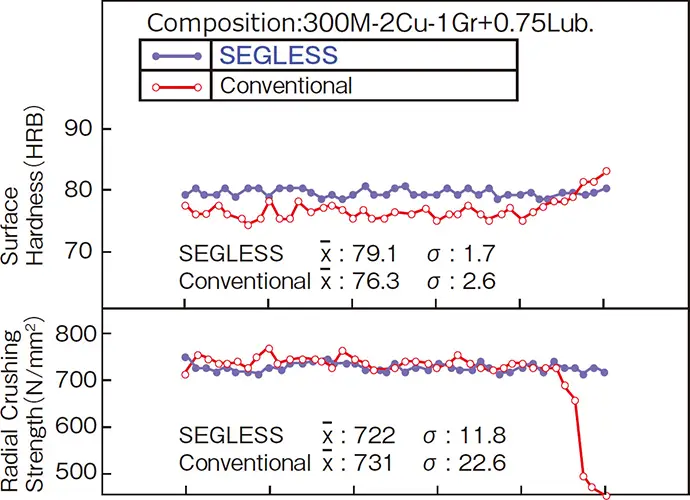

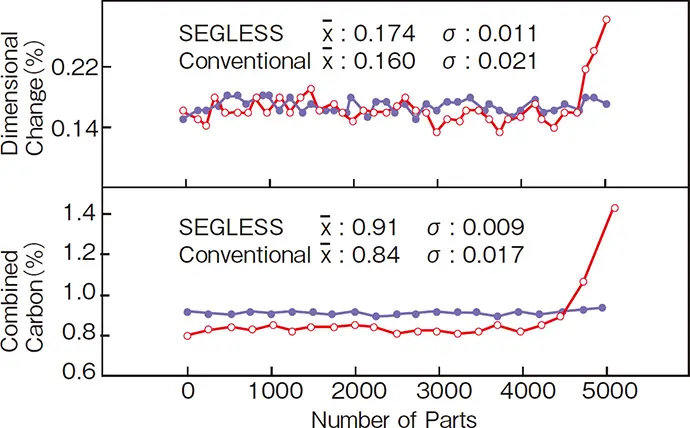

- Quality stability during continuous production

Since graphite powder does not concentrate inside the hopper towards the end of continuous production, the properties are always constant, enabling stable part manufacturing.

Adhesion Stage of Graphite Powder

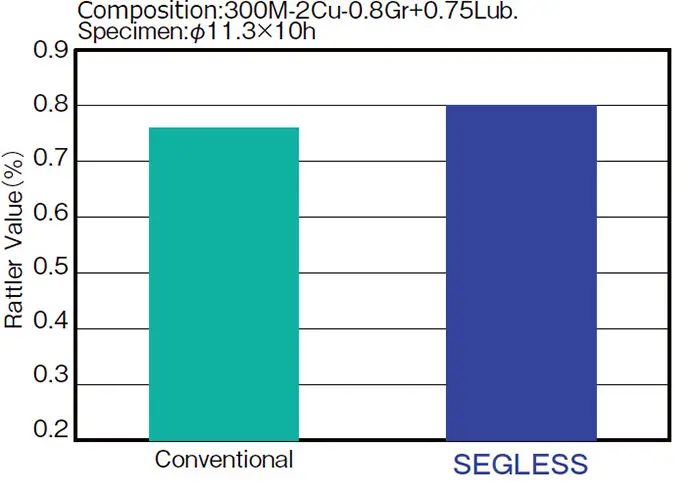

Power Properties

Stability during Continuous Production

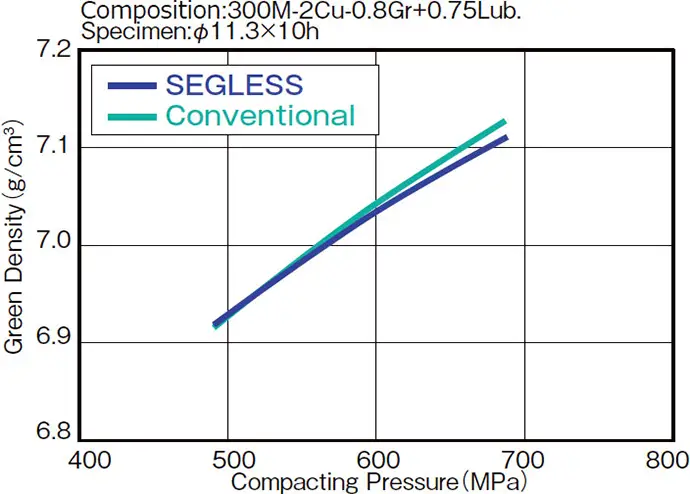

Compressibility

Compactability

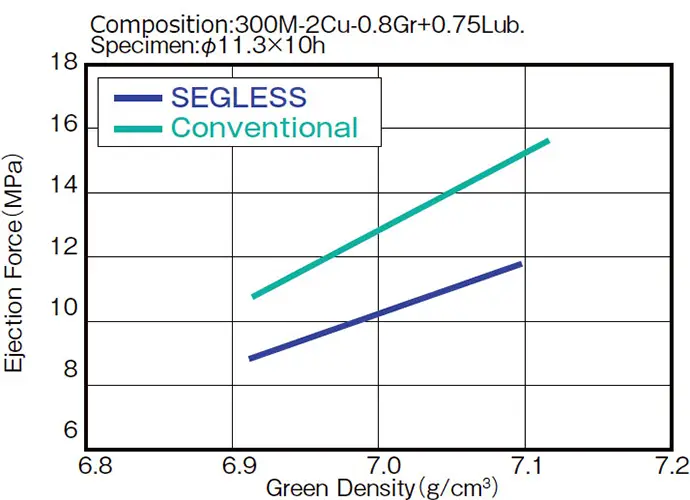

Ejection Force

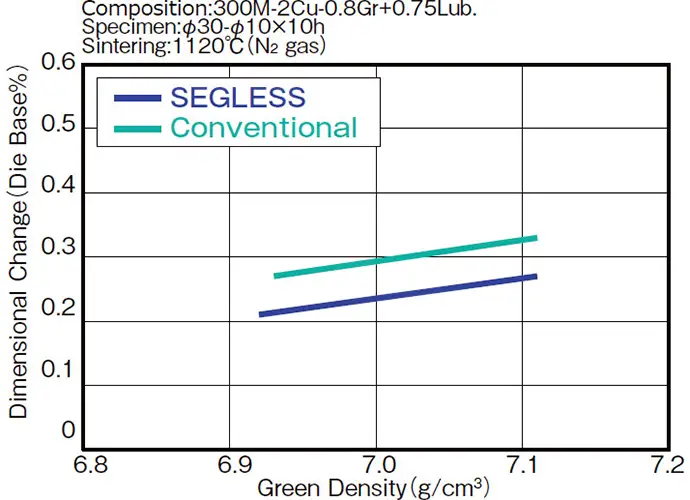

Dimensional Change Rate of Sintered Body

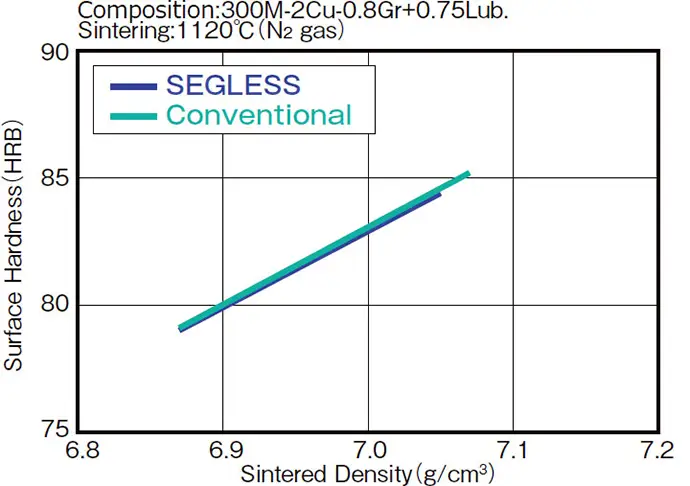

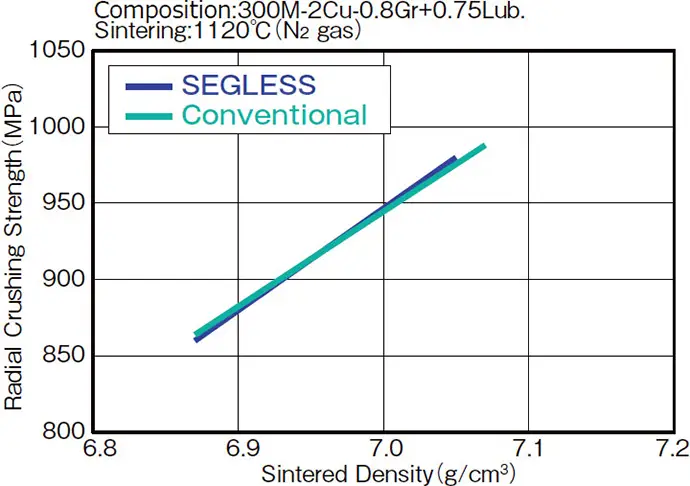

Mechanical Properties of Sintering Materials

Applications

Automotive, motorcycle, industrial machinery, office equipment, and electrical equipment parts

Contact Us

You can reach us by clicking the inquiry button.