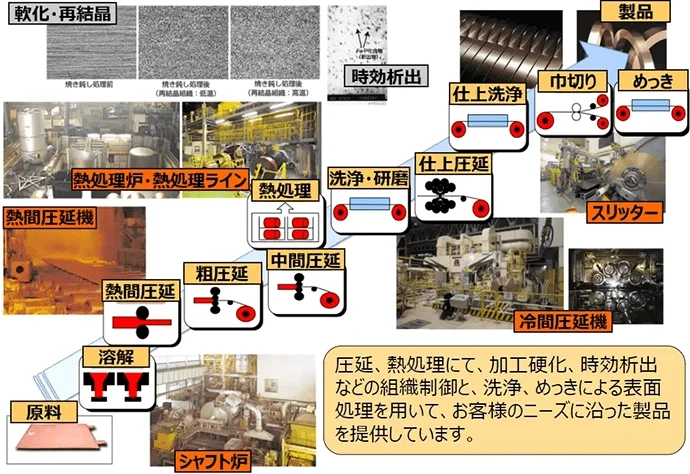

Manufacturing Process for Copper Strip

Overview of the Manufacturing Process for Copper Strip

Typical Manufacturing Process

- (1) Melting and Casting

Melting and casting of special alloys is carried out using shaft furnaces, coreless furnaces, and other equipment.

- (2) Hot Rolling

The casted ingots are heated to 700–1,000℃ to homogenize the structure and composition.

While still hot, the heated slabs are rolled from approximately 250 mm thickness down to about 20 mm.

- (3) Cold Rolling

The material is cold rolled to the specified thickness at a reduction ratio that achieves the required mechanical properties.

This includes rough rolling, intermediate rolling, and finish rolling. Rolling mills vary by roll arrangement: 2-high, 4-high, 6-high, or multi-high mills (12-high, 20-high).

- (4) Annealing

Annealing is performed at 300–700℃ for several hours to up to one day.

The annealing atmosphere is either non-oxidizing or reducing, and heating is conducted indirectly by heating the atmosphere.

- (5) Pickling and Polishing

-

- Degreasing: Removes oil such as rolling oil

- Pickling: Removes oxide film formed on the surface during batch annealing, etc.

- Brush polishing: Removes oxide film more efficiently

- Hot water rinse / rust prevention: Suppresses formation for new oxide film after removal

- (6) Slitting

The stock is slit to customer-specified widths and lengths (or unit weight).

- (7) Plating

Tin plating is applied to the surface of the material.

After plating, the surface is reflowed (melted) to improve resistance to whisker formation and solderability.

- (8) Inspection, Packaging, and Shipping

After slitting (or plating), shape and material inspections are performed to ensure that only high-performance, high-quality copper strip products are shipped.

Contact Us

You can reach us by clicking the inquiry button.