Kobe Steel’s Aluminum

- Aluminum Castings and Forgings

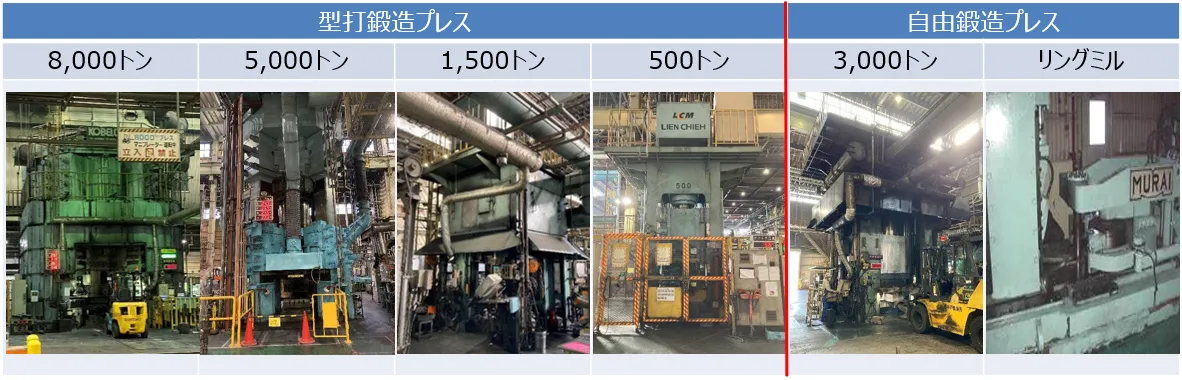

- Main Equipment for Aluminum Castings and Forgings

- Alloys Handled in Aluminum Castings and Forgings

- Aluminum Extrusion

- Main Extrusion Equipment

- Extrusion Awards and Recognitions

- Suspension Components

- Main Equipment for Suspension Components

- Suspensions Awards and Recognitions

Aluminum Castings and Forgings

The Aluminum Casting & Forging Plant has three manufacturing processes.

Each process is capable of producing products with distinct characteristics, as described below.

| Sand Mold Casting Process |

Applications: Aircraft and other industrial uses

|

|---|---|

| Forging Process (using Hydraulic press) |

Applications: Aircraft, semiconductor manufacturing equipment, rolling stock, turbochargers, etc.

|

| Machining Process |

Applications: Aircraft, semiconductor manufacturing equipment, LCD manufacturing equipment

|

Main Equipment for Aluminum Castings and Forgings

Alloys Handled in Aluminum Castings and Forgings

| Category | Name | Alloy No. | Characteristics, applications, etc. |

|---|---|---|---|

| Main alloys used for aluminum forging and aluminum casting | High-strength alloys | 7050 | Excellent ductility, toughness, and resistance to stress corrosion cracking. Used for aircraft components and high-speed rotating parts. |

| 7075 | Strongest among forging alloys; widely used for aircraft and marine components. One of the highest-strength aluminum alloys, widely used due to its ability to be produced in a variety of types and sizes. |

||

| 7N01 | High strength and corrosion-resistant alloy for welded structures. Used for train (Shinkansen) and aircraft components. | ||

| 2014 | High strength with good forgeability and ductility. Used for aircraft, railway vehicles, automotive parts, and general structural parts. | ||

| Heat-resistant alloys | 2219 | An aluminum alloy with excellent high-temperature strength, creep resistance, and weldability, used in high-stress aerospace components such as rockets. | |

| 2618 | A heat-resistant aluminum with high strength at elevated temperatures, used in aerospace components requiring high-temperature performance, as well as in general heat-resistant applications. | ||

| 4032 | An aluminum alloy with high strength at medium temperatures (around 200°C), low thermal expansion, and excellent wear resistance, used for forged pistons. | ||

| Corrosion resistant alloys | 6061 | Good ductility, toughness, and corrosion resistance. | |

| 5083 | An aluminum alloy with excellent corrosion resistance, weldability, and mechanical properties at low temperatures, used for flanges in LNG applications. | ||

| 5052 | Medium-strength alloy with excellent corrosion resistance and formability. |

Aluminum Extrusion

bumper reinforcements

With the growing need to shed vehicle weight and enhanced crash safety regulations, high-strength 7000-series extruded aluminum materials are being adopted for components such as bumper reinforcements and door beams. We offer optimal proposals for alloy selection, cross-sectional shapes, and machining geometries tailored to meet requirements for crash performance, vehicle styling, and more.

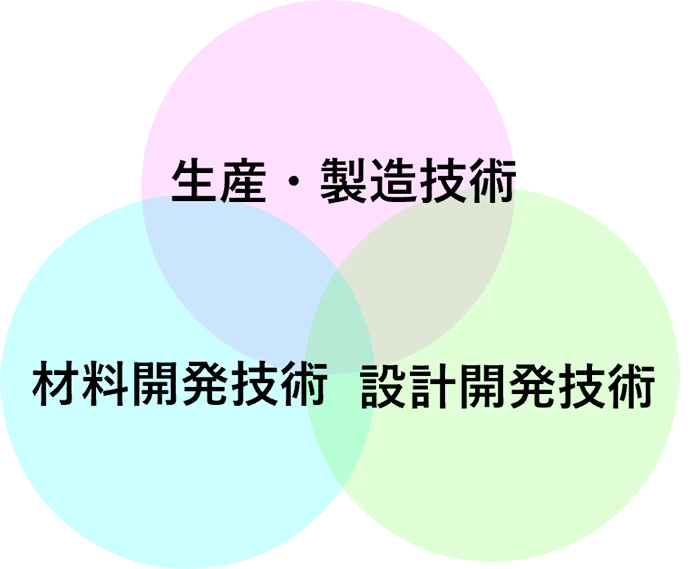

- Production and Manufacturing Technologies

-

- Integrated production system from alloy production to extrusion, inspection, and shipping.

- Equipped with extrusion presses of various tonnage capacities, enabling production of shapes that meet customer requirements.

- High-level machining capabilities using advanced equipment enable the manufacture of components for automotive applications.

- Material Development Technology

-

- Optimal alloy proposals that leverage extensive expertise in aluminum alloy development.

- Development of numerous new aluminum alloys, including high-strength alloys for aircraft, motorcycles, and automobiles, and alloys for rolling stock.

- Design Development Technology

-

- We use flow analysis in our extrusion die design and also offer design expertise for complex cross-sectional dies to meet diverse customer needs.

- We can propose optimal alloys, cross-sectional shapes, and processing geometries to meet performance requirements such as crash performance and vehicle styling.

Main Extrusion Equipment

Extrusion Awards and Recognitions

| Description | Award | |

|---|---|---|

| 2019 | Development of high-strength aluminum extrusion alloy for automotive bumpers (7K55 alloy) | Japan Aluminium Association Award – Development Award |

Suspension Components

Aluminum is being actively used for automotive suspensions due to the need for lighter weight.

Kobe Steel has realized weight reductions of more than 40% over conventional steel parts, and dominates the market share in Japan.

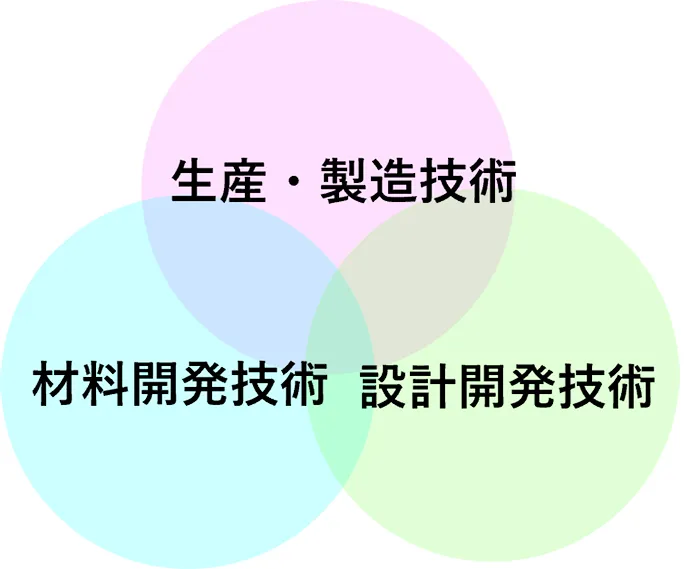

- Production and Manufacturing Technologies

-

- Fully integrated production system from alloy production to forging, inspection, and shipping.

- Die and process design expertise that leverages the forming capacity of our 6,300-ton mechanical forging press enables cost-effective production of medium to large suspension components.

- Our continuous billet casting process can cost-effectively produce large-diameter casting bars which become raw material.

- Material Development Technology

-

- Our proprietary high-strength 6000-series alloy achieves weight reductions of 40% or more than cast iron.

- Material strengthening is achieved by reviewing the conditions from material composition and casting bar production to forging and heat treatment.

- Design Development Technology

-

- We offer optimized geometries designed to be light and manufacturable through the use of analysis techniques.

Main Equipment for Suspension Components

Suspensions Awards and Recognitions

| Description | Award | |

|---|---|---|

| 2020 | A skillful operator equipped with extensive forming press manufacturing know-how gained from many years of job experience. | Medal with yellow ribbon |

| 2023 | Development of a new process for hot forging high-strength aluminum | METI Minister’s Award |

Contact Us

You can reach us by clicking the inquiry button.