Milestones in Kobe Steel’s Titanium

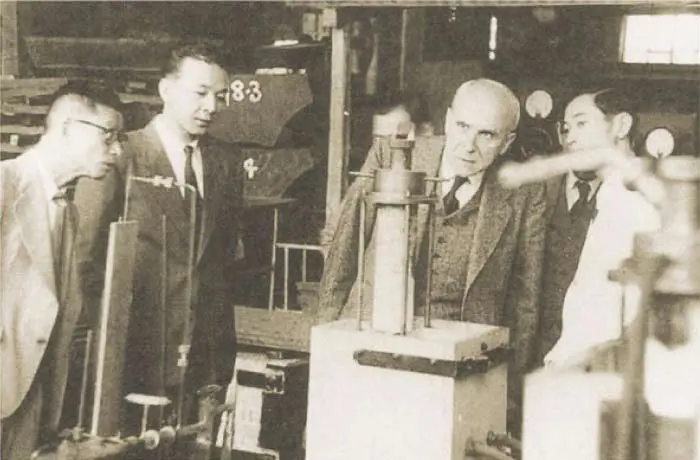

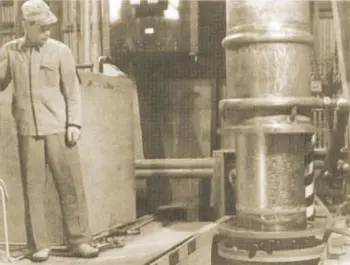

Kobe Steel was the first company in Japan to begin research and development on titanium in 1949, and has the longest history with titanium than any other company.

With over 60 years of experience in titanium, we have supported the growth of industries across a wide range of fields.

| 1949 |

|

|---|---|

| 1953 |

|

| 1954 |

|

| 1955 |

|

| 1959 |

|

| 1972 |

|

| 1979 |

|

| 1981 |

|

| 1982 |

|

| 1985 |

|

| 1986 |

|

| 1987 |

|

| 1993 |

|

| 1997 |

|

| 1998 |

|

| 1999 |

|

| 2001 |

|

| 2002 |

|

| 2006 |

|

| 2007 |

|

| 2008 |

|

| 2011 |

|

| 2011 |

|

| 2012 |

|

| 2013 |

|

| 2015 |

|

| 2016 |

|

| 2021 |

|

Contact Us

You can reach us by clicking the inquiry button.