Typical Manufacturing Processes for Aluminum

Aluminum Castings and Forgings

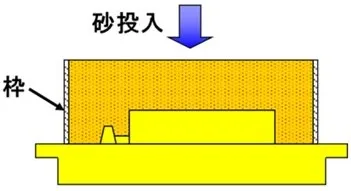

Sand Casting

- With our proprietary technology and robust quality assurance system, we deliver highly reliable cast products.

Kobe Steel has earned longstanding recognition as a top-tier manufacturer of sand-cast aluminum and magnesium products for aircraft. Building on technologies and a quality control system developed at the former Nagoya Plant, Daian Works continues to meet increasingly advanced customer needs—especially for aircraft parts.

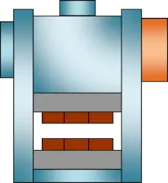

Forging(using Hydraulic press)

- From large aircraft components to mid- and small-size parts, we apply proprietary technologies to meet diverse customer needs.

The hydraulic press forging division is equipped with hydraulic forging presses rated at 8,000, 5,000, 3,000, 1,500, and 500 tons. We design optimal production processes matched to aluminum forging product size and supply forged components across a wide range of fields—including aircraft, marine, rolling stock, and vacuum equipment.

Machining

- Under stringent quality control, we achieve the high level of dimensional precision demanded in advanced industries.

Typically, cast and forged parts become final products only after undergoing various machining processes. At Daian Works, we add value to products through machining, anodizing, and other customer-requested treatments. High-precision machining is especially in demand for semiconductor manufacturing equipment such as chambers and shower plates. We meet these needs with a full suite of machining equipment, including machining centers to support a broad range of product requirements.

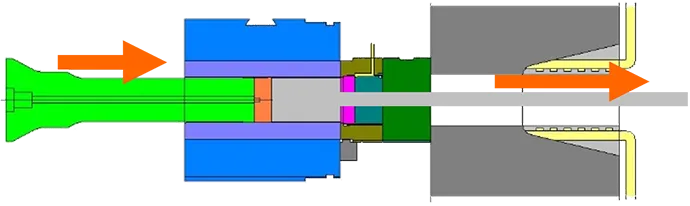

Aluminum Extrusion

- Manufacturing Process for Aluminum Extruded Products

An integrated mass production line from billet casting, extrusion, to heat treatment and inspection

To meet customer needs, we apply various fabrication techniques to produce components such as bumpers and door beams for automotives.

Suspension Components

Kobe Steel manufactures aluminum forgings for suspension components used in automotive chassis systems. Throughout our proprietary alloy development, we have achieved higher material strength and reduced weight reduction. We also employ a combination of innovative technologies—including multi-die layout for one-heat continuous forging on our large 6,300-ton mechanical forging press, and structural analysis-based design proposals—to meet a wide range of needs, particularly for midium- to large-size suspension components.

Contact Us

You can reach us by clicking the inquiry button.