What are Kobe Steel’s Steel Casting and Forging/Steel Powder?

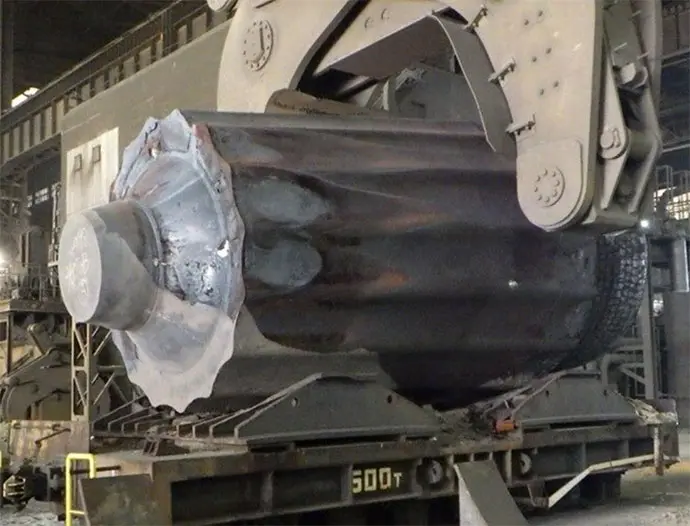

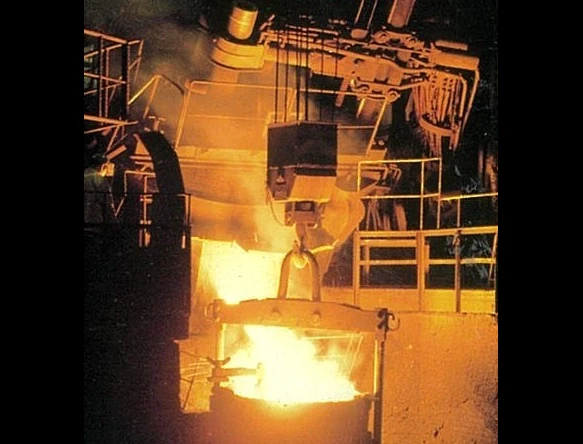

Kobe Steel’s Steel Casting and Forging

Steel is an alloy composed primarily of iron and carbon, and it is an essential material used across a wide range of fields, including automotives, construction, shipbuilding, and home appliances.

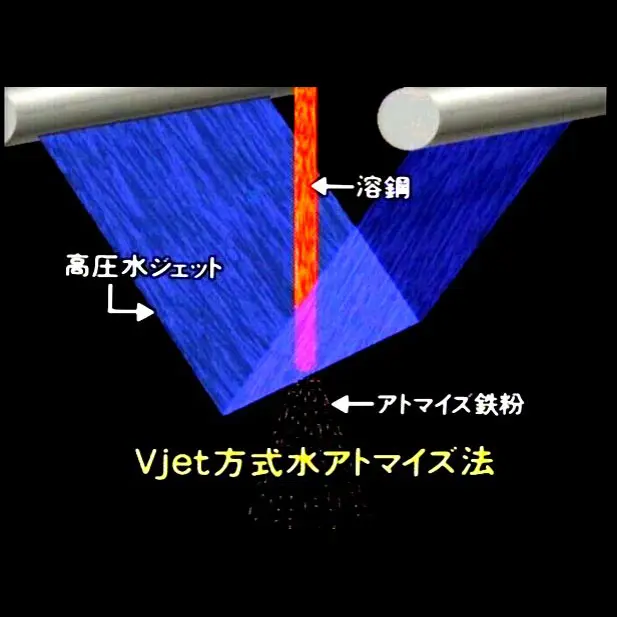

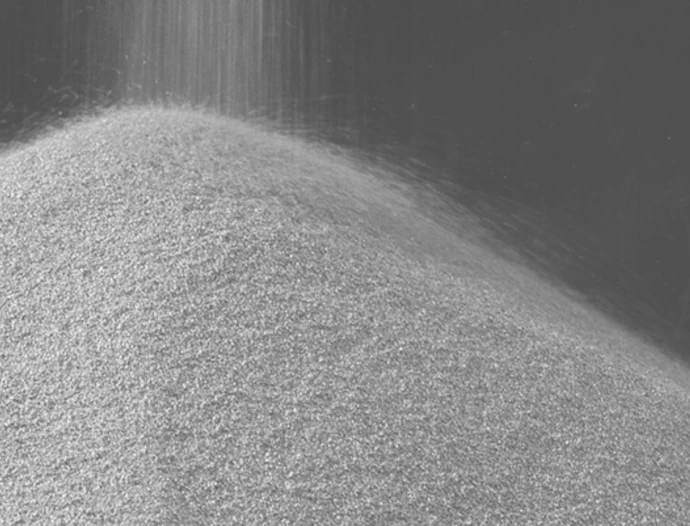

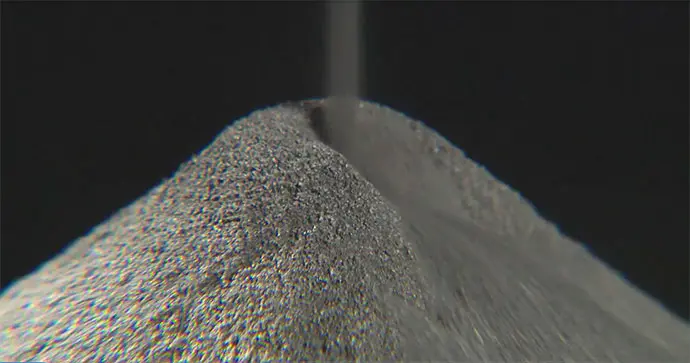

Kobe Steel’s Steel Powder

Steel is an alloy made up of iron and carbon, offering greater strength and toughness than pure iron. Most steel powders—such as pure iron powder and low-alloy powder produced by the Steel Powder Unit—are used as raw materials in the powder metallurgy process to manufacture sintered parts for automotives, industrial machinery, and home appliances.

These parts are characterized by the formation of steel through carbon diffusion during sintering, rather than by adding carbon at the raw material stage—a process adopted to accommodate press compacting methods*.

The Steel Powder Unit also produces steel powders for metal injection molding**.

These powders are ultra-fine (with an average particle size of around 10 μm) for excellent sinterability to improve the final part density. The powder is turned into steel by adding carbon at the powder stage to suit injection molding.

In addition to sintered parts, steel powders are also used in applications such as body warmers, deoxidizers, chemical reactions, and environmental purification. These applications take advantage of the chemical reactivity of elemental iron, allowing steel powder to be used across a wide range of fields.