Typical Production Processes for Steel Casting, Forging, and Steel Powders

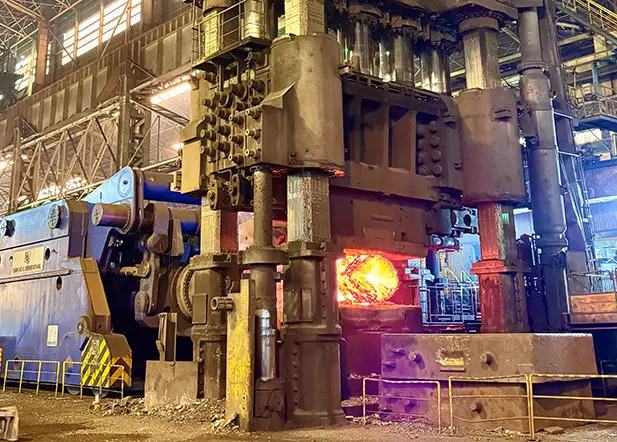

Typical Manufacturing Process for Steel Casting and Forging

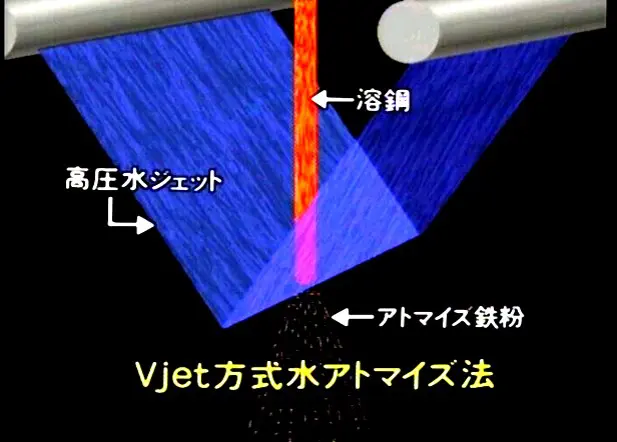

Typical Production Process for Steel Powder

As a pioneer in atomized steel powders, Kobe Steel introduced the V-jet water atomization method in 1970. This method enables stable, high-volume production of high-quality pure steel powders and low-alloy powders. Our Steel Powder Plant handles the entire production process—from melting pig iron and scrap generated by steelworks and other sources to the atomization process that pulverizes molten steel, the reduction process that removes oxide films, and the final packaging process for shipment.

For powder metallurgy applications, we also operate a mixing line that blends graphite, copper powder, lubricants, and other additives with the base powder. This allows us to produce premixed powders (mixed powders for press compacting applications).

Contact Us

You can reach us by clicking the inquiry button.