Steel Powder

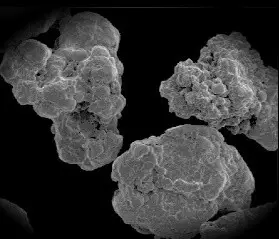

In 1970, Kobe Steel was the first company in Japan to begin the manufacture and sale of atomized steel powder. In the years since, our steel powder products have been recognized for their excellent properties across various fields including automotive components, and have become widely used for powder metallurgy, environmental applications (remediation of soil and groundwater contaminants) under the brand name of ECOMEL®, welding rods, deoxidizers and magnetic applications under the brand name of MAGMEL™.

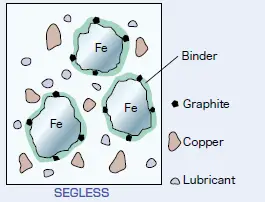

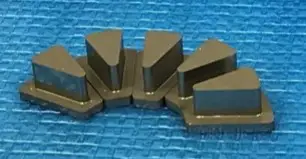

Due to its excellent compressibility, steel powder makes it easier to form large high-density and high-strength components.

Kobe Steel completed a new steel powder plant in 1992 to ensure a consistent supply of superior quality steel powder while leveraging the expertise that we have developed over many years. Since then, we have been supplying high-quality steel powder with superior production technologies under updated strict quality control systems.

Related Information

Contact Us

You can reach us by clicking the inquiry button.