High Strength and High Formability Copper Alloy CAC™ 60

High strength, Excellent stress relaxation resistance and Good bend formability

CDA No.64760

Features

- High strength exceeding 580MPa, suitable for use in small terminals

- Excellent bend formability compared to other Cu-Ni-Si alloys, providing greater flexibility in terminal and connector designs

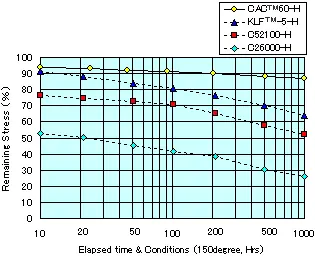

- Excellent stress relaxation resistance. Applicable to SAE class 4

- Achiving 44% IACS in electrical conductivity, making it suitable for high-current cumponents

Applications

- Small terminals and connectors for automotive wire harness

- Special terminals for consumer and industrial use, etc.

Nominal Compositions

Cu-1.8Ni-0.4Si-1.1Zn-0.1Sn (mass%)

Characteristics

Physical Properties

| Specific Gravity | 8.9 |

|---|---|

| Coefficient of Thermal Expansion (293~573K) | 17.3 x 10 -6 /K |

| Thermal Conductivity (293K) | 197 W/m.K |

| Electrical Resistivity (293K) | 39.2 nΩ.m |

| Electrical Conductivity (293K) | 44 % IACS |

| Modulus Elasticity (293K) | 127 GPa |

- *Note: The above are typical characteristics.

Mechanical Properties

| Temper | Tensile Strength MPa |

Yield Strength MPa |

Elongation % |

Vickers Hardness MHv: 4.9N |

|---|---|---|---|---|

| H | 600–700 | 580 | 10 min | 180–220 |

| EH | 640–740 | 640 | 3 min | 190–230 |

- *Note 1: Figures in yield strength are nominal values.

- *Note 2: The above tensile strength and hardness are standard specifications. Technical specifications will be determined according to consumer requests.

90°V-Type Bend-Formability (MBR)

| Temper | Good Way | Bad Way |

|---|---|---|

| H | 0 | 0 |

| EH | 0.5 | 0.2 |

- *Note: The above are typical characteristics. The value slightly varies depending on the thickness of specimens.

Contact Us

You can reach us by clicking the inquiry button.