High Strength and High Conductivity Copper Alloy SuperKFC™

Enhanced characteristics superior to the original KFC™

CDA No.19240

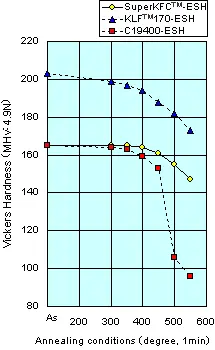

SuperKFC™ is a precipitation-hardened copper alloy with fine iron-phosphorus intermetallic compounds in the matrix, formed by adding iron and phosphorus to copper, in a similar manner to the original KFC™. With increased amounts of iron and phosphorus content, this product achieves both higher strength and higher electrical conductivity than the original by employing the process metallurgy approach. SuperKFC™ offers properties comparable to or higher than C19400 but contains a smaller amount of iron content, enabling higher yield rate, direct bear wire-bonding, and improved surface conditions, and lowering overall manufacturing costs.

Features

- High electrical and thermal conductivity, and higher electrical conductivity than C19400

- High strength and high electrical conductivity. Available for a variety of applications. (Temper ESH)

- Free of smut contamination during pre-plating process and etching process.

- Excellent stamping formability and etching formability

- Excellent bondability for gold and copper wires

- Excellent platability for a variety of metals, such as Ag, Ni, Sn, solder, etc., achieving high Ag-plating reflection required for high-luminosity LED leadframes

- Excellent solderability

Applications

- Leadframes for QFP and QFN packages

- Inner-frame for heat spreader, etc.

Nominal Compositions

Cu-0.3Fe-0.1P (mass%)

Characteristics

Physical Properties

| Specific Gravity | 8.9 |

|---|---|

| Coefficient of Thermal Expansion (293~573K) | 17.5 x 10-6/K |

| Thermal Conductivity (293K) | 311 W/m.K(Temper H 337W/m.K) |

| Electrical Resistivity (293K) | 22.1 nΩ .m(Temper H 20.3nΩ .m ) |

| Electrical Conductivity (293K) | 78 %IACS(Temper H 85%IACS) |

| Modulus Elasticity (293K) | 122 GPa |

- *Note: The above are typical characteristics.

Mechanical Properties

| Temper | Tensile Strength MPa |

Elongation % |

Vickers Hardness MHv: 4.9N |

|---|---|---|---|

| H | 430–530 | 3 min | 130–160 |

| ESH | 500–600 | 3 min | 150–180 |

- *Note: The above tensile strength and hardness are standard specifications. Technical specifications will be determined according to consumer requests.

90°V-Type Bend-Formability (MBR)

| Temper | Good Way | Bad Way |

|---|---|---|

| H | 0.5 | 1.0 |

| ESH | 1.0 | 1.5 |

- *Note: The above are typical characteristics. The value slightly varies depending on the thickness of specimens.

Contact Us

You can reach us by clicking the inquiry button.